Automotive mobility is saying farewell to combustion engines and heading for a carbon-free electric future. This far-reaching technology shift is stimulating the creativity and innovative powers of developers. Their intelligent solutions not only support sustainability and global climate protection, but also convince, or even inspire, customers in daily life. Next-generation EVs are playing to their…

Continue readingNews: Startseite

Optimum sustainability, performance or cost effectiveness? Choose all three!

Tomorrow’s automotive mobility will be sustainable and carbon neutral. While that would be impossible for internal combustion engines, for battery-electric drives the goal is in sight. From the considerable heights already scaled, developers are aiming higher still by improving the operation and production of electric motors. Innovative technologies are boosting efficiency and range while lowering…

Continue readingDevelopment if a multi-Speed Two-Drive-Powertrain

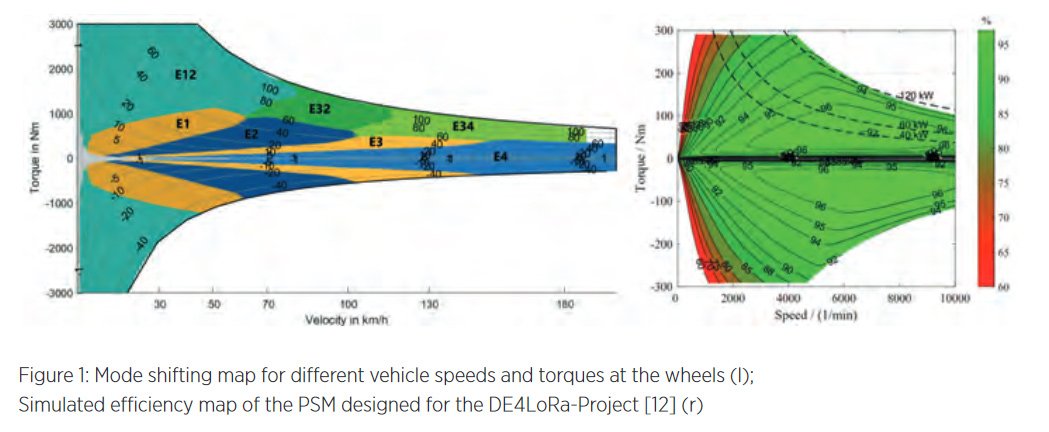

Aaron Kappes , Steffen Frei , Sebastian Luz , Prof. Stephan Rinderknecht, Institute for Mechatronic Systems, TU Darmstadt; Institute for power electronics and control of drives, TU Darmstadt An electric Two-Drive-Powertrain using two electric machines is presented, which allows a highly efficient over all usage. The multi-motor approach achieves a downsizing effect, when one motor is deactivated during…

Continue readingHOERBIGER: Innovative Solutions for Electric Drivetrains

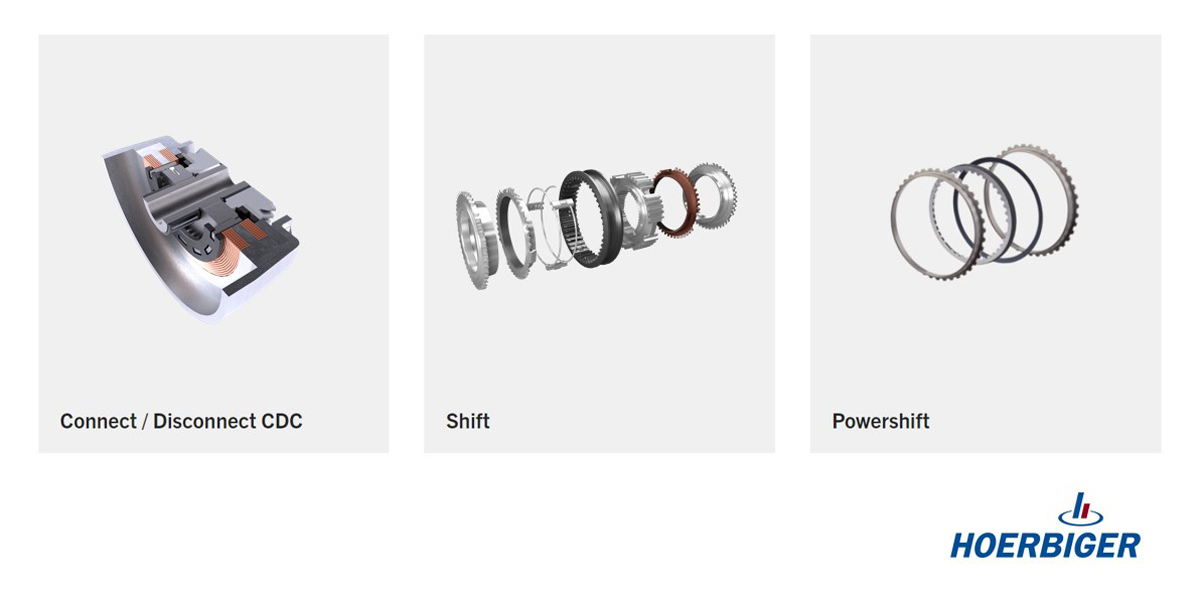

Your reliable system and component supplier for future mobility From development to production of innovative components and complete systems for conventional and alternative powertrains - HOERBIGER offers you everything from a single source. The portfolio for electrified drive trains includes transmission synchronizers and innovative shift elements for coupling and decoupling as well as components and…

Continue readingRuiping Wang, Geely Auto Senior VP, Plenary Speech at CTI SYMPOSIUM Germany 2022

Ruiping Wang, Geely Auto Senior Vice President, joined CTI SYMPOSIUM GERMANY 2022 as plenary speaker via video from China. See her contribution “Geely’s strategy and practice in powertrain electrification” as video and hear about BEV growth rates, the regulatory context, and Geely´s drive solutions and outlook on HEV, PHEV and BEV in the Chinese market.

Continue readingElringKlinger: Metalobond – Supporting Direct Cooling Systems

ElringKlinger Metalobond is a new full face gluing system for laminated stacks with a high sealing capability to support direct cooling systems in rotors and stators and increase performance. With increasing rotation speed and less installation space in advance electric engine concepts, heat becomes more and more an issue. The best way to cope with…

Continue readingJJE Advances Electromagnetic ClutchTechnology to a New Level

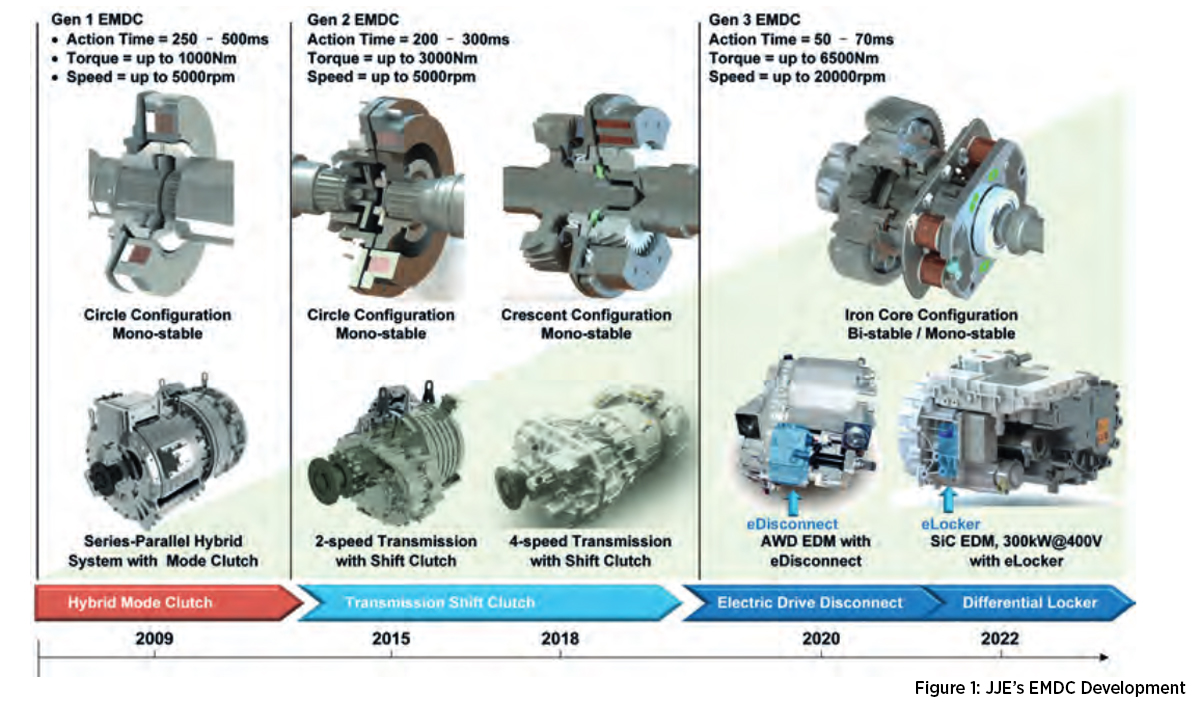

JJE DirectFluxTM Mono-stable and Bi-stable Electromagnetic Clutches for Disconnect and Differential Locker Applications Jing-Jin Electric (JJE) has been developing electromagnetic clutches for various electric drive applications over a decade. Instead of using “reluctance” magnetic force, JJE electromagnetic clutches utilize direct magnetic force – flux in the same direction as the magnetic force – which is…

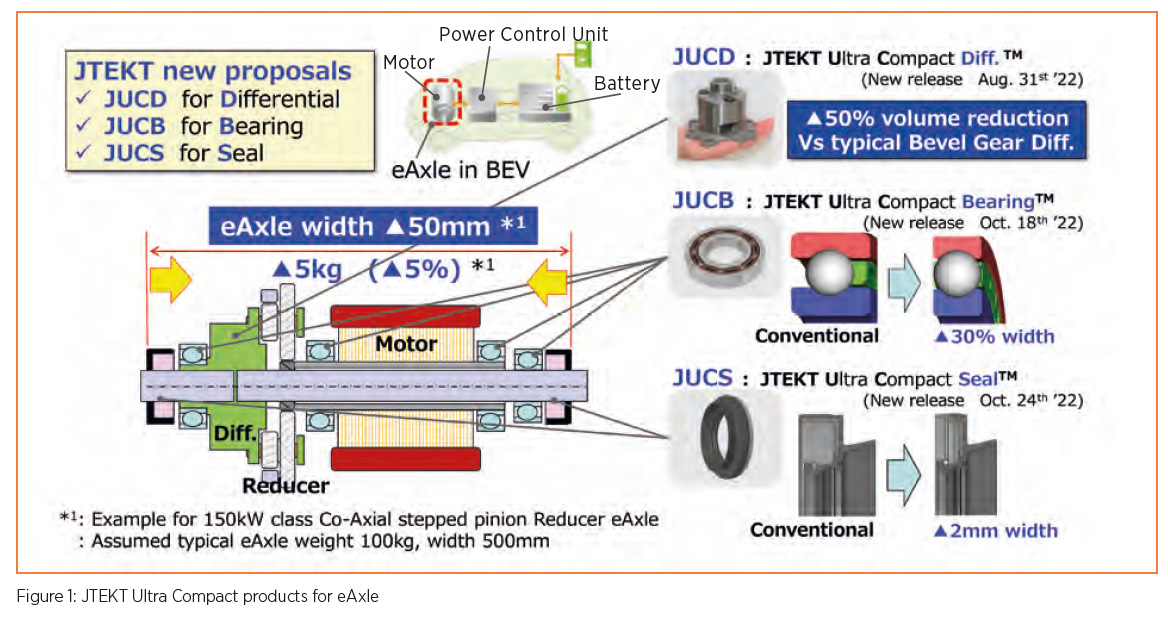

Continue readingDevelopment of “JTEKT Ultra Compact Diff.” for eDrive system

Contribution to further eAxle compactness and higher power density Makoto NISHIJI, Senior General Manager / Chief Engineer, Driveline CE Department, Automotive Business Unit, JTEKT Corporation In response to the strong expansion of the battery electric vehicle (BEV) market, JTEKT has developed and just announced “Ultra Compact” product series, JTEKT Ultra Compact BearingTM, JTEKT Ultra Compact…

Continue readingMagna’s eBeam™ Family for Truck and LCV Electrification

Although light trucks and light commercial vehicles are used for different purposes, the requirements are similar in terms of robustness, performance, package compatibility, etc. The Magna eBeam™ family offers a flexible electrification solution that covers class 1 to 6 trucks as well as LCVs up to 7,5 tons.

Continue readingThe Automotive Industry Drives Sustainability

The days of viewing the powertrain as a system on its own are gone. As the 21st CTI Symposium in Berlin showed, the challenges even extend well beyond the vehicle itself. Software and networking play an increasingly central role; circular economy and social responsibility are extending the responsibilities of OEMs and suppliers; and competition for…

Continue reading