ElringKlinger MetaloBond™ is a lamination stack technology using a full face glue system with high sealing capability to support direct rotor and stator cooling for increased e-motor performance.

With increasing rotation speed and less installation space in advanced electric engine concepts, heat becomes more and more an issue.

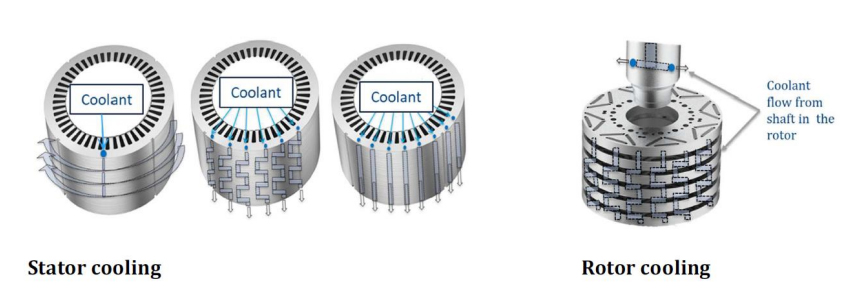

The best way to cope with this issue is to avoid heat generation by reducing electromagnetic losses, e.g. in the iron core. A further important approach is to use an efficient direct cooling system to get heat out of the system and therefore increase continuous performance of the electric motor significantly.

ElringKlinger is very experienced to produce materials < 0.30 mm. The target is to reduce the eddy current losses in the system and by doing so, reducing the generated heat.

The packages produced with the MetaloBond™ technology achieve good values in strength and setting behavior.

MetaloBond™

Tensile lap shear strength (EN1465) 22 N/mm²

Peel resistance (EN1464) 3,4 N/mm

As a further approach, a direct cooling system can be used to remove heat. If the direct cooling system shall be designed within the iron core, a reliable and lifetime durable sealing between the single layers of the iron core must be ensured.

The ElringKlinger MetaloBond™ technology guarantees a high sealing capability. Due to its clear focus on sealing performance, it allows more design freedom versus other full face glue systems on the market.

With MetaloBond™ made by ElringKlinger, cooling channels can be placed with a minimum distance to the perimeter and still seal pressures up to 200 bar, even under thermal cycling and thermal shock conditions.

This allows to place cooling channels where they are needed. Either close to the hot spots or close to the perimeter to reduce interruption of magnetic flux. The result is an efficient cooling system with an increase in continuous performance.

As a full-service supplier, ElringKlinger is able to support you with the full range of services from heat flux calculation, lasered and stamped prototypes to fluid flow testing with thermal cycling or shock.

We are looking forward to meet you at our booth no. A7 at CTI in Novi!