How a dual-drive EDU, design-to-CO₂e thinking, and battery innovation converge to deliver <10 kWh/100 km energy demand and >94% system efficiency – ready for vehicle application.

Dipl.-Ing. (FH) Wilhelm Vallant, Product and Business Development Manager Transmission & E-Axle, AVL List GmbH

The automotive industry is at a turning point, and OEMs face a dual challenge: delivering uncompromised performance while meeting stringent sustainability and cost targets. AVL’s latest technology demonstrator addresses this challenge head-on, setting new benchmarks for energy efficiency, lifecycle CO₂e reduction, and system integration.

The project’s objectives were clear: achieve an Electric Drive Unit (EDU) average cycle efficiency of over 94 % (WLTP) and reduce vehicle energy demand to below 10 kWh/100 km. These goals demanded a holistic approach – optimizing the EDU, battery systems, and vehicle aerodynamics in unison.

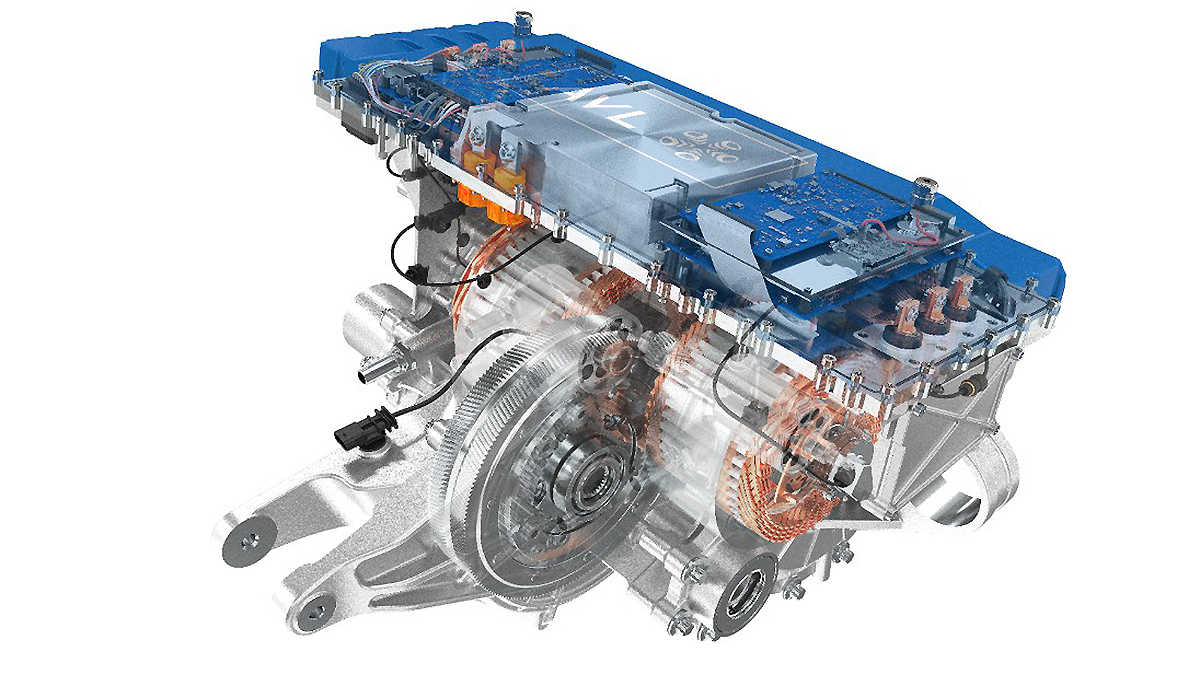

At the heart of the demonstrator vehicle lies a dual-motor EDU featuring two Permanent Magnet Synchronous Machines (PMSMs), a compact single stage spur-gear transmission, and a dual Silicon Carbide (SiC) inverter. One motor operates continuously for maximum efficiency, while the second engages only for boost and recuperation via a dog clutch. This intelligent operating strategy minimizes losses across real-world duty cycles. Using AVL’s Powertrain System Optimizer (PSO) and AI-driven Design of Experiments methodology ensured optimal sizing and control strategies. The result: validated average EDU efficiencies of 94.1 % in real-world testing and 94.4 % in customer-specific cycles.

Efficiency alone is not enough. AVL integrated lifecycle CO₂e considerations from concept to production, applying a “Design-to-CO₂e” methodology to further reduce material usage, cutting system weight, cost, and lifecycle CO₂e.

Two battery concepts complement the EDU: A performance-optimized pack leveraging silicon-anode/NMC811 chemistry, advanced evaporative side cooling, and cell-to-pack integration for maximum energy density.

A cost-optimized LFP pack featuring cylindrical cells, multifunctional cooling plates, and CO₂-based evaporative cooling – eliminating the need for a separate low-temperature circuit and reducing system complexity.

Vehicle-level efficiency was enhanced through a fully virtual aerodynamic optimization process, achieving a 23 % drag reduction in simulation and 20 % in coast-down testing – critical to meeting the sub-10 kWh/100 km energy demand target.

This demonstrator is more than a showcase; it’s a blueprint for scalable, production-ready solutions. By combining cutting-edge EDU design, battery innovation, and lifecycle sustainability, AVL empowers OEMs to deliver electric powertrains and complete vehicle designs that excel in efficiency, performance, and environmental responsibility.