JJE DirectFluxTM Mono-stable and Bi-stable Electromagnetic Clutches for Disconnect and Differential Locker Applications

Jing-Jin Electric (JJE) has been developing electromagnetic clutches for various electric drive applications over a decade. Instead of using “reluctance” magnetic force, JJE electromagnetic clutches utilize direct magnetic force – flux in the same direction as the magnetic force – which is named “DirectFluxTM”. A mono-stable clutch is engaged by actuation current, and disengaged by spring force when the current is off. A bi-stable clutch will only change its state when there’s an affirmative pulse of command current; otherwise, it will hold its state. Earlier this year, JJE launched industry’s first bi-stable electromagnetic clutch for automotive applications.

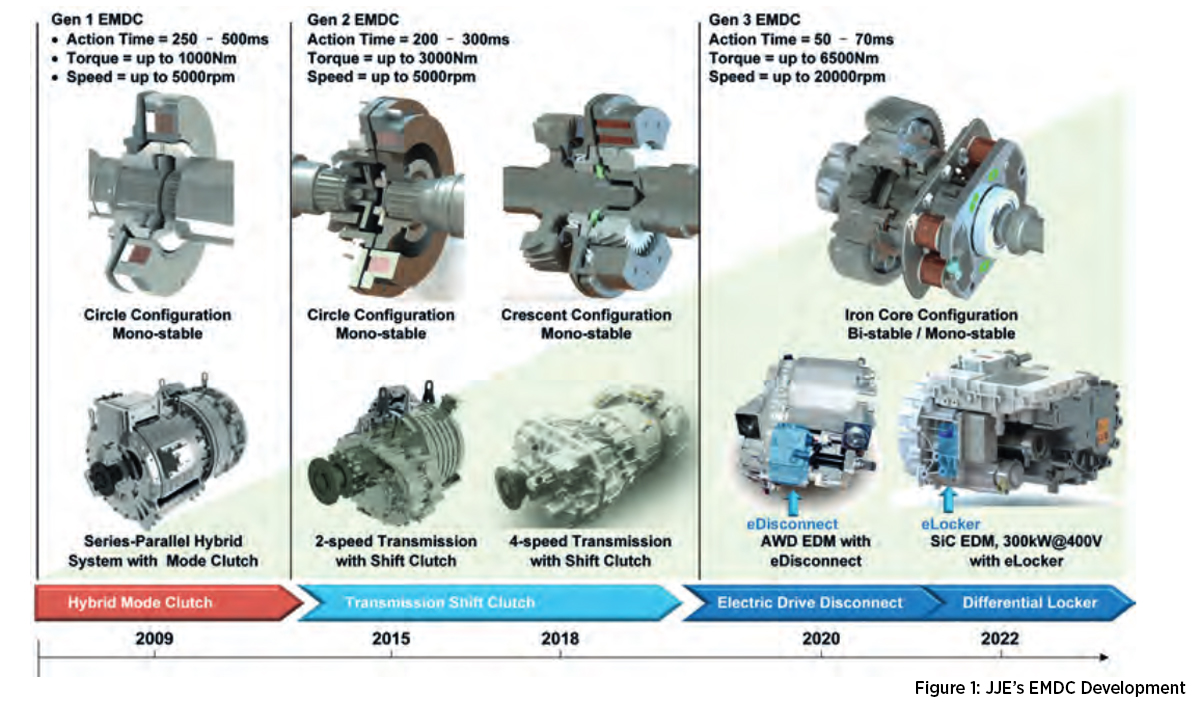

The technology roadmap for developing an electromagnetic dog clutch (EMDC) plays a key role in the product’s developing stage. Back to 2009, JJE started to develop the electromagnetic clutch in “DirectFluxTM” concept. The first generation (Gen 1) EMDC product is a circle configuration, mainly applied on hybrid systems as a hybrid mode clutch, which was very successful in China’s commercial market.

In 2017, the 2nd generation (Gen 2) EMDC product was launched, and expanded its application to transmission shifting after optimization over mechanical design. The “crescent” configuration was developed and added in the JJE’s EMDC family.

In early 2019, JJE began the development of 3rd generation (Gen 3) EMDC. The third generation (Gen 3) EMDC features further innovations. It has both mono-stable and bi-stable options. It overcame some limitations of the existing design. Coils evolved to smaller solenoids, and magnetic circuit are further optimized to reduce flux leakage. The Gen 3 EMDC is more capable, faster, functionally safer, and more energy efficient.

DirectFluxTM Electromagnetic Clutch

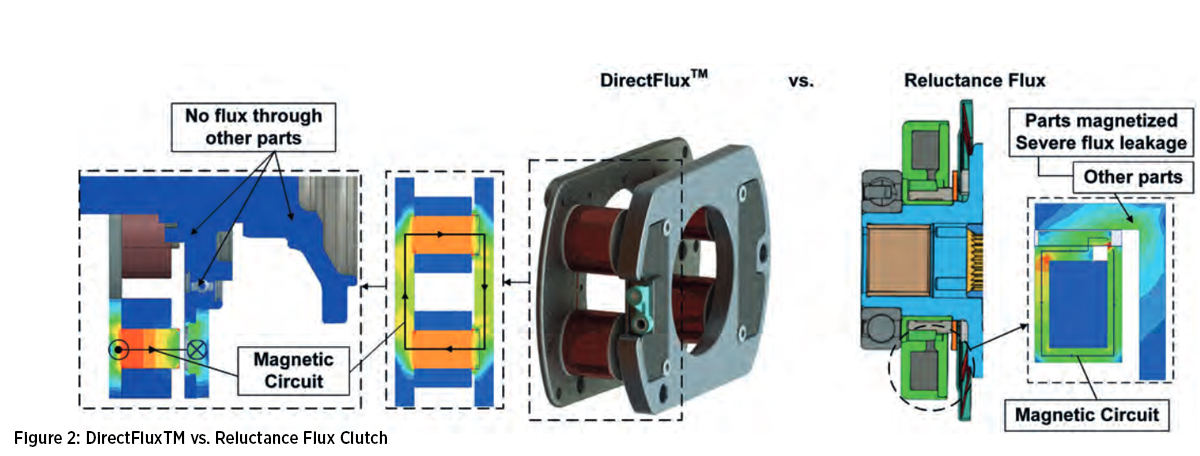

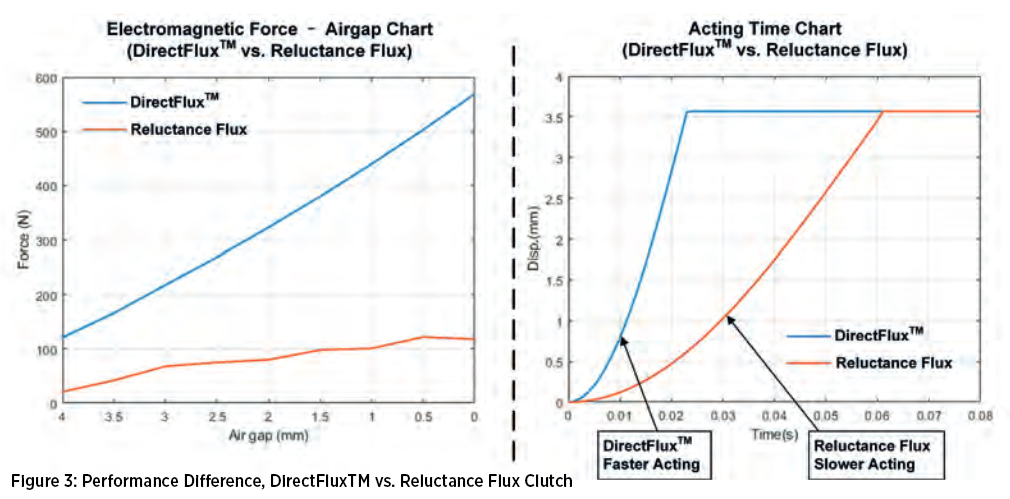

JJE’s DirectFluxTM mono-stable electromagnetic clutch has several advantages because of its unique magnetic circuit design and mechanical structure. Compared to the more conventional reluctance flux magnetic circuit design, the DirectFluxTM design greatly reduces flux leakage, therefore it utilizes the magnetic flux to generate force more effectively. The reluctance flux design cannot avoid magnetization of parts near flux circuit, or “flux leakage”, which cause less effective utilization of the magnetic flux.

Because of the more effective flux utilization, the DirectFluxTM clutch has much higher electromagnetic force than reluctance flux clutch, therefore it acts 2-3 times faster, as shown in the charts.

Bi-stable Electromagnetic Clutch

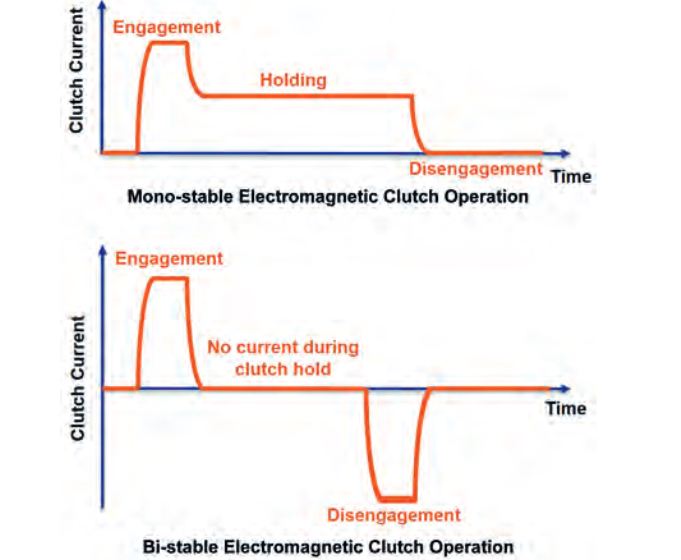

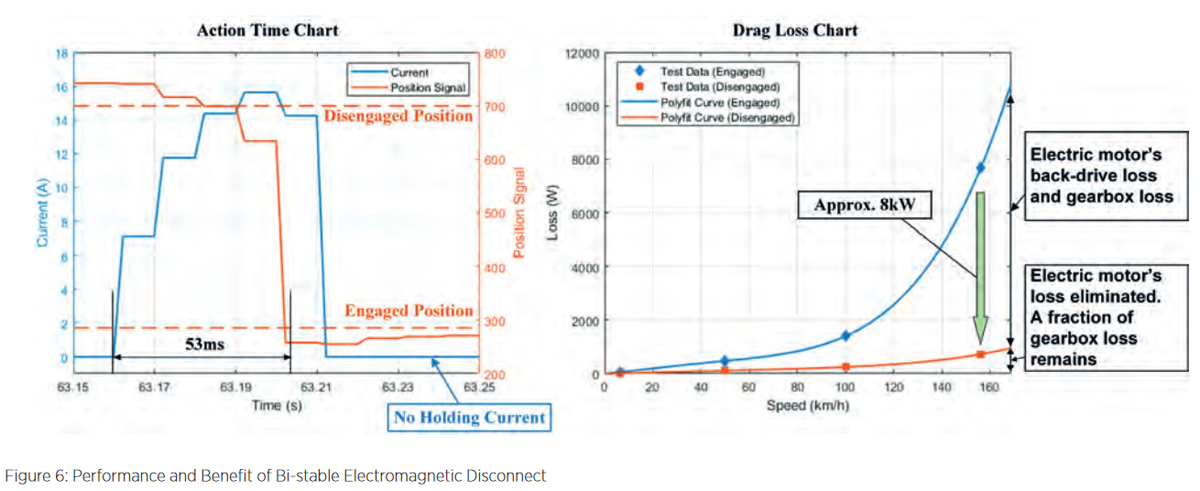

The bi-stable electromagnetic clutch – still based on JJE’s DirectFluxTM electromagnetics – is an innovation beyond JJE’s mono-stable electromagnetic clutch. It uses permanent magnets to hold the clutch in its en-gaged position, while still allowing the electromagnetic coil to “push” the clutch plate away while disengaging. As the clutch can self-hold at both engaged and disengaged positions, there is no need for holding current as the mono-stable clutch does. The operation current curve exactly illustrates the difference between the mono-stable and bi-stable. For bi-stable clutch, the operation only needs to provide a current pulse to switch the clutch’s state (see Fig.).

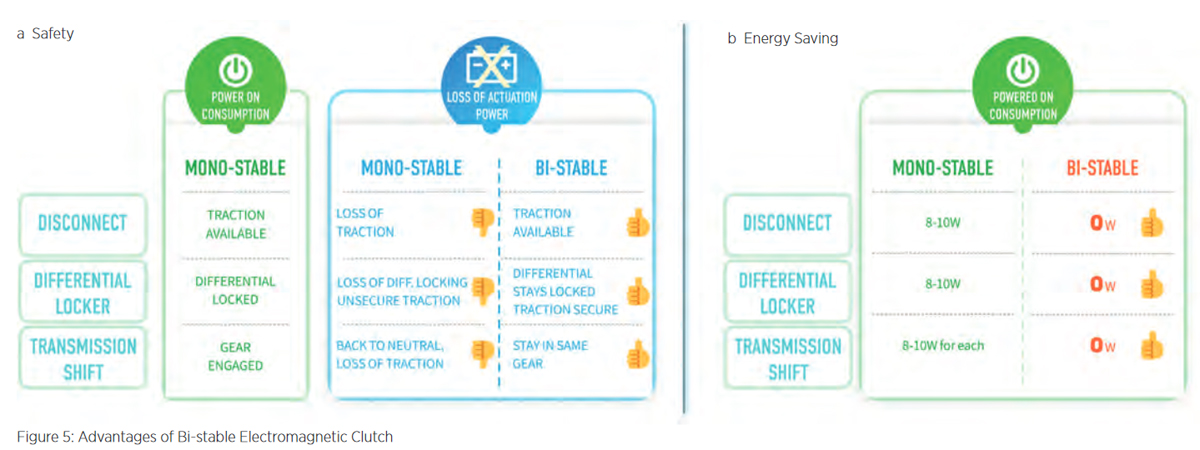

The bi-stable clutch is inherently fail-safe as it won’t change state in the event of loss of holding current. This feature brings the bi-stable clutch a higher safety level than mono-stable clutch for disconnect, differential lock-er, and transmission shift applications. As far as energy consumption, the bi-stable clutch’s feature of “zero hold-ing current” achieves the zero consumption.

The bi-stable clutch is inherently fail-safe as it won’t change state in the event of loss of holding current. This feature brings the bi-stable clutch a higher safety level than mono-stable clutch for disconnect, differential lock-er, and transmission shift applications. As far as energy consumption, the bi-stable clutch’s feature of “zero hold-ing current” achieves the zero consumption.

Figure 4: Operation Comparison Between Mono-stable and Bi-stable Clutch

Disconnect

JJE’s mono-stable clutch has already been successfully applied on electric drive disconnect. In an offset, layshaft reduction gearbox, the disconnect clutch is on the output and is integrated with differential. Compared with disconnect on the input shaft or on the layshaft, the output shaft discon-nect cuts out most mechanical losses. JJE is also introducing bi-stable electromagnetic clutch to disconnect application. There is no holding current or power consumption when the clutch is engaged. It is mechanically fail-safe in the event of critical electrical or control fault. When the vehicle is in AWD state, all-wheel power will be maintained for consistency; when the vehicle is in the 2WD state – or secondary axle disconnected – the secondary axle won’t be suddenly engaged, which would cause big jerk, or even wheel lockup at low traction. DirectFluxTM bi-stable clutch has a great performance on the action time. The differential locker and disconnect driven by DirectFluxTM bi-stable EMDC have been tested on JJE’s Dynamometer. The average action time is less than 70ms, and only current pulses are needed for engagement and disengagement. With JJE’s disconnect clutch, the drag loss reduction is remarkable. In a typical 200kW electric drive unit with permanent magnet motor, at 150km/h vehicle speed, the drag loss reduction is greater than 90%, or from nearly 8kW to less than 500W.

Differential Locker

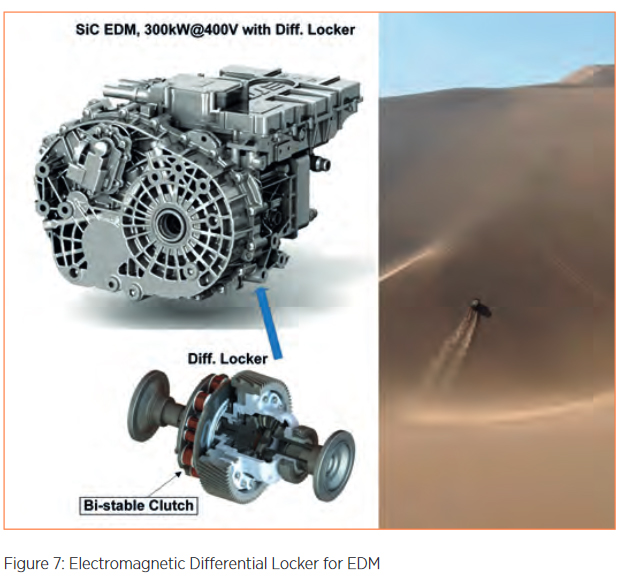

JJE debuted industry’s first electromagnetic bi-stable differential locker at 2022 CTI US. Bi-stable’s greatest advantage is still fail-safe – in the event of critical electrical or control fault, this bi-stable feature can prevent sudden locker release and dangerous loss of tractionThis bi-stable DirectFluxTM differential locker will be used in high capability pick-up trucks, SUVs and off-road vehicles in independent electric drive module (EDM) or eBeam axles. It will be launched into production in 2023 in JJE’s newest 6000Nm, 300kW Silicon Carbide EDM for a high-end 4×4 SUV by a leading OEM, which features over 100% gradeability.“JJE has been developing and producing electromagnetic clutch for over a decade”, says Ping Yu, JJE’s Chairman and Chief Engineer, “we have pioneered electromagnetic dog clutch’s application in many areas and generated multiple global patents. The introduction of the bi-stable clutch technology is more exciting – it brings security like a mechani-cal sleeve clutch while maintaining or even improving all other great aspects of an electromagnetic clutch. It will further reinforce our leadership in electric drive technology”.

JJE debuted industry’s first electromagnetic bi-stable differential locker at 2022 CTI US. Bi-stable’s greatest advantage is still fail-safe – in the event of critical electrical or control fault, this bi-stable feature can prevent sudden locker release and dangerous loss of tractionThis bi-stable DirectFluxTM differential locker will be used in high capability pick-up trucks, SUVs and off-road vehicles in independent electric drive module (EDM) or eBeam axles. It will be launched into production in 2023 in JJE’s newest 6000Nm, 300kW Silicon Carbide EDM for a high-end 4×4 SUV by a leading OEM, which features over 100% gradeability.“JJE has been developing and producing electromagnetic clutch for over a decade”, says Ping Yu, JJE’s Chairman and Chief Engineer, “we have pioneered electromagnetic dog clutch’s application in many areas and generated multiple global patents. The introduction of the bi-stable clutch technology is more exciting – it brings security like a mechani-cal sleeve clutch while maintaining or even improving all other great aspects of an electromagnetic clutch. It will further reinforce our leadership in electric drive technology”.