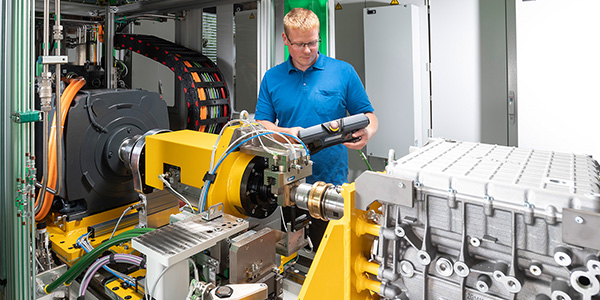

Image caption: Standardization of test benches for e-drives at top quality

teamtechnik Group in Freiberg/Germany has thoroughly standardized its system platform for end-of-line test benches. This results in a reduction in development and delivery times and also in the costs for the test benches. At the same time, their quality of testing sets new standards.

The test platform was developed by teamtechnik for testing and calibrating complete e-drives, e-axes, electric motors, and hybrid transmissions. It is designed for drive voltages of up to 1000 volts and for high braking torques and braking power, and as an energetically closed system it enables the complete recovery of electrical energy.

The structure of the test benches, with the three component areas of measurement and drive technology, the test object, and automation, is essentially always the same. Only the interfaces to the test object and the automation and test parameters of the test software are specific to the product. This modular concept, with tested and high-performance components, enables teamtechnik to create the test benches much faster and to integrate them into a production line. They are nevertheless intended for the most diverse production environments, whether these be prototype or pre-series, small series or large series production.

Since the mechanical and electrical designs of such test benches are already highly developed, teamtechnik achieves added value for the customer through careful application. For example, with flexible clamping and connecting concepts and test software based on customer requirements. In addition, teamtechnik employees know the behavior of the measurement technology and components towards each other very accurately. They know about the influences of ambient conditions, technical faults and design tolerances on the measurement results. By means of careful design and construction, they are able to shorten the test cycles and to optimize the reproducibility of the results. Under the motto ‘The system is greater than the sum of its parts’, teamtechnik always optimizes the e-drive test benches on the basis of customer requirements and for the best possible test results.

A brief portrait

teamtechnik Group

teamtechnik Group is one of the international market leaders for production technology, assembly and functional test systems. The company, based at Freiberg am Neckar, Germany, focuses on developing and building custom automation solutions for the e-mobility, medtech, and new energy sectors. A proven strength is its high level of competence in the fields of software and control technology. teamtechnik was founded in 1976 and today has production sites worldwide.

Contact:Philipp Enzel

Telephone: +49 7141 7003-299