glulock® – A unique in-tool bonding technology for e-laminations in motor stacks

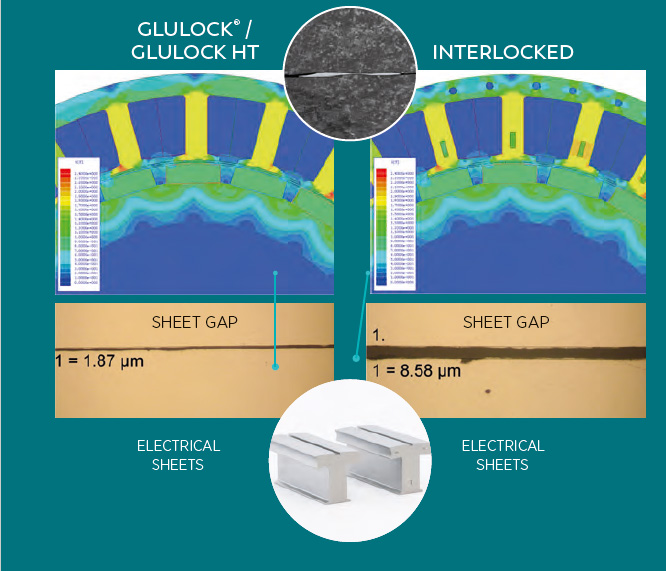

Motor-cores have been build by mechanically interlocking individual motor laminations for decades. With materials in laminations for e-motor cores becoming thinner and thinner and increased efficiencies of electrified propulsion systems this process of mechanically interlocking the „stacks“ has become more and more difficult and less efficient.

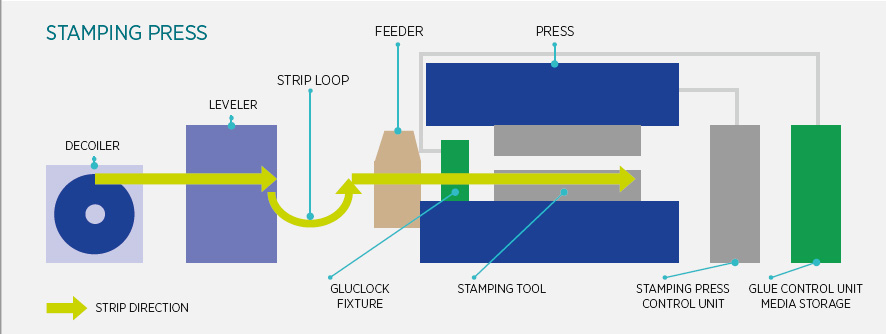

With glulock®, an in-tool bonding process for e-laminations, Feintool provides solutions fully integrated into the stamping process.

To address the shortcomings of mechanically interlocked e-sheets the industry developed alternative secondary bonding processes that eliminates any sheet gaps and improves stacking factors to above 96%.

Traditional Secondary Bonding Processes Result in Commercial Shortcomings

Traditional secondary bonding processes such as “Backlack” have several commercial disadvantages. First, the bonding agent is applied to the actual raw material which results to be locked into certain raw material suppliers. In addition, the already applied bonding agent is subject to a limited shelf life and in some of the grades, sensitive to heat exposure during shipping for example in a container or truck during the hot summer months.

However, the biggest shortcoming is that a secondary, costly energy and labor-intensive process is necessary to stack and bond the individual sheets together to a rotor and stator core exposing them to a secondary heating process after they have been stamped as single laminations.

The Solution – glulock®

The unique glulock in-tool bonding process for e-laminations provides solutions fully integrated into the stamping process. Feintool’s glulock is an e-sheet lamination bonding process that continuously applies dot adhesive integrated in the stamping tool during the stamping process. The result is an instantly bonded e-motor core without any additional and expensive secondary operations or the need to use proprietary raw material with a bonding agent that results in limited shelf life and logistic challenges.

“ With the glulock technology, its consistent further development, and our proximity to customers and the market, I am firmly convinced that we have already found the right answers to the requirements of the future.”

“ With the glulock technology, its consistent further development, and our proximity to customers and the market, I am firmly convinced that we have already found the right answers to the requirements of the future.”

MARKUS LOCK, Head of R&D and Engineering, Feintool System Parts

17 years of innovation and countless engineering hours and practical trials are the foundation of the glulock system. An advanced control system with various functions for consistently monitoring flow and valve functions are at the heart of the technology.

Temperature Resistant

In addition to the mechanical/magnetic advantages of glulock – glulock is chemical resistant and offers a temperature resistance up to 180 degrees Celsius / 356 degrees Fahrenheit. For example, glulock can be used in ATF oil within a temperature class H.

An Evolution to glulockMD® technology

An Evolution to glulockMD® technology

The advantage of glulock is that the system is fully integrated in the high-speed stamping press as part of the e-lamination tooling. The 2-component glue is applied in real time and is currently tested with stroke rates exceeding 200 strokes per minute. With the possibility to apply multiple dots in a controlled size and a 360-degree pattern it is possible to place several glue dots on the stamped e-lamination in such a way that an almost full-surface bonding is ensured.

What are the advantages of glulockMD?

With the trend towards bonding laminations and therefore increase performance and reduce losses in the e-motor glulockMD offers following technical benefits:

- Improved flux density compared to a mechanical interlocked stack/motor core

- Higher stacking factor (>96%); reduced stack tolerance

- Processing of thinner material (up to 0.1mm)

- Improved shape accuracy

- High stability of stack

- Improved efficiency

- Increased torque

- High process speed

Improved flux density:

The glulockMD bonding process results in a significant reduction of sheet gap – therefore achieving a higher stacking factor compared to mechanical interlocking.

Sealing Properties

Further developments in electric motor show that, in addition to the growing mechanical and thermal requirements, their cooling also has potential for optimization.

Further developments in electric motor show that, in addition to the growing mechanical and thermal requirements, their cooling also has potential for optimization.

Especially for e-motors with higher and higher rpm’s the trend is to have the cooling integrated into the rotors and stators. This requires impermeable stacking, sealing and surface bonding. With glulock it is possible to place several glue dots on the sheet in such a way that an almost full surface bonding is ensured. In addition to the sealing function, the bonding on the yoke and tooth segments ensures additional rigidity of the motor core stack.

Proven Technology

We are seeing a lot of success by major OEMs and tier suppliers with our glulock technology. Feintool is producing all the motor stacks for a major German OEM for their latest, most efficient electric motor with glulock technology.

ABOUT FEINTOOL

Feintool is a world-leading technology group specializing in fineblanked and formed components that provide high-precision, functional, and critical automotive parts.

We offer production of electro motor lamination, electro core stacks, and copper parts for BEV and hybrid vehicles. Where you make it makes a difference. Feintool helps to keep your production line running. You’ll get the highest quality parts, made with the most advanced vertically integrated processes. Because together we can.

Feintool US operates a technology center in Cincinnati, a sales office in Detroit, and specialized production plants in Cincinnati and Nashville.

Learn more at: www.feintool.us/power/.