Andrew Wood, Driveline Fluids Technologist, Infineum UK Ltd

Calum Sugden, Driveline Fluids Technologist, Infineum UK Ltd

The transportation industry is working to decarbonise, and commercial vehicle manufacturers are exploring a range of low and zero carbon propulsion options, including electrification. New opportunities to formulate tailored driveline eFluids are emerging, as the electrified truck and bus market develops.

The evolving electric drive architectures used in this vehicle segment have specific protection and performance needs.

Full battery electric propulsion is one option commercial vehicle Original Equipment Manufacturers (OEMs) are exploring.

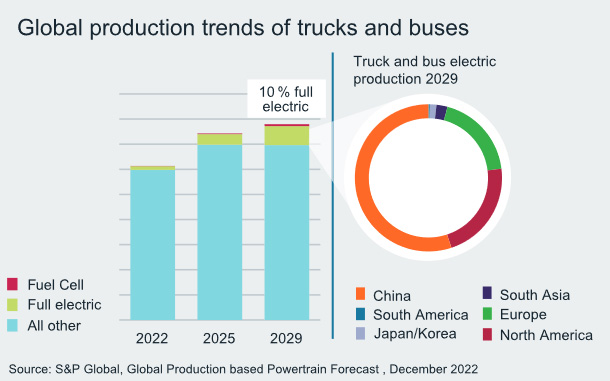

In 2021 it was estimated that just over 4% of the combined global bus and truck fleet was fully electric. Looking ahead, as the pressure to decarbonise intensifies, forecasters suggest that by 2029 some 10% of commercial vehicles rolling off the production line will be electric, with the majority produced in China, and small volumes coming from Europe and North America (see visual 1).

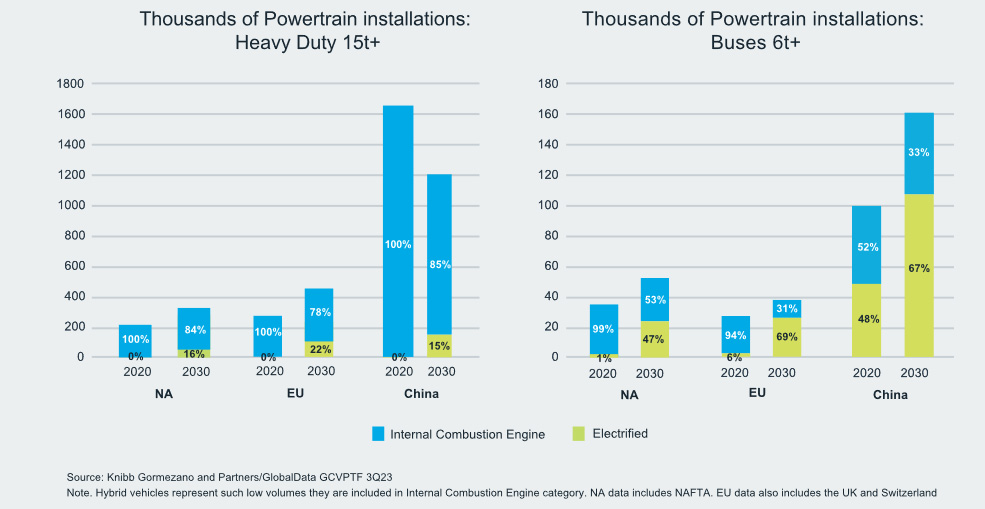

However, more detailed data suggests a faster electrification rate in buses compared to heavy-duty trucks.

Shorter trips and return to base operations where charging can be done overnight, plus local government measures to reduce air pollution in city centres, makes the transition less difficult for buses (see visual 2).

As the hardware evolves, we can expect to see three key drive systems in the market − central drive, integrated eAxle and distributed wheel/ specific hub motors.

Two separate fluids are typically used (one to cool the motor and another to protect the gears), because the position of the motor and gear type means it is challenging currently for one fluid to meet all the requirements of these systems.

Fluid requirements

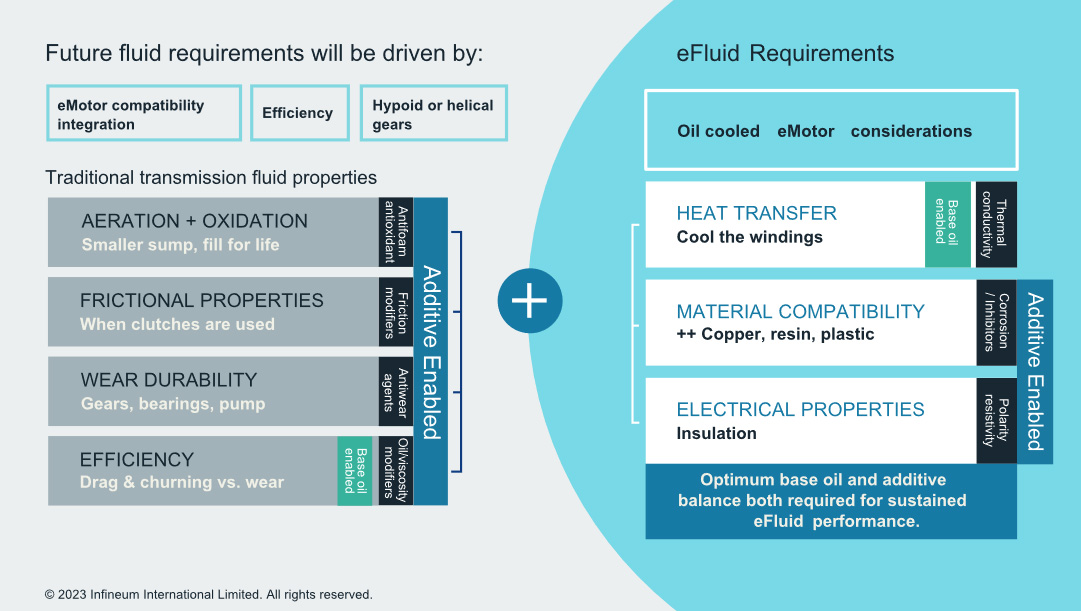

In addition, it is challenging to deliver sufficient hardware protection in these fully electric models with the conventional automatic transmission fluids (ATF) and axle oils used today (see visual 3).

Next generation eFluids will need to deliver not only traditional transmission fluid properties but also new eFluid requirements including improved heat transfer, better materials compatibility, and higher volume resistivit (see visual 4).

Heat transfer for eMotor cooling

Cooling electric motors is recognised as a critical function of electric vehicle transmission fluids. Infineum has carried out extensive assessments to determine the most important properties of eFluids for heat transfer.

While the impact of viscosity and additive technology have been key focal points during tests carried out in different motor configurations, attention has also been directed towards the effect of operating conditions such as flow rate and motor torque.

Heat generation tests revealed that low viscosity fluids offer significant performance benefits versus higher viscosity formulations – delaying derating of stator windings and showing lower steady state temperatures.

However, when moving to lower viscosity lubricants, cooling benefits provided need balancing by an additive technology which also delivers sufficient wear protection.

Materials compatibility

eMotors introduce a wide range of materials into the drivetrain including insulating material, copper wire and connections, aluminium, plastics, and sealants. Many OEMs consider copper compatibility to be one of the most important design parameters for eFluids, because electronic circuit boards are increasingly in contact with or immersed in oil, so full compatibility is required.

The ASTM D130 procedure is one of the most common methods used to study the impact of copper corrosion. But now, newer methods, including energised circuit board tests that involve the passage of an electric current, are also being used to better understand copper corrosion.

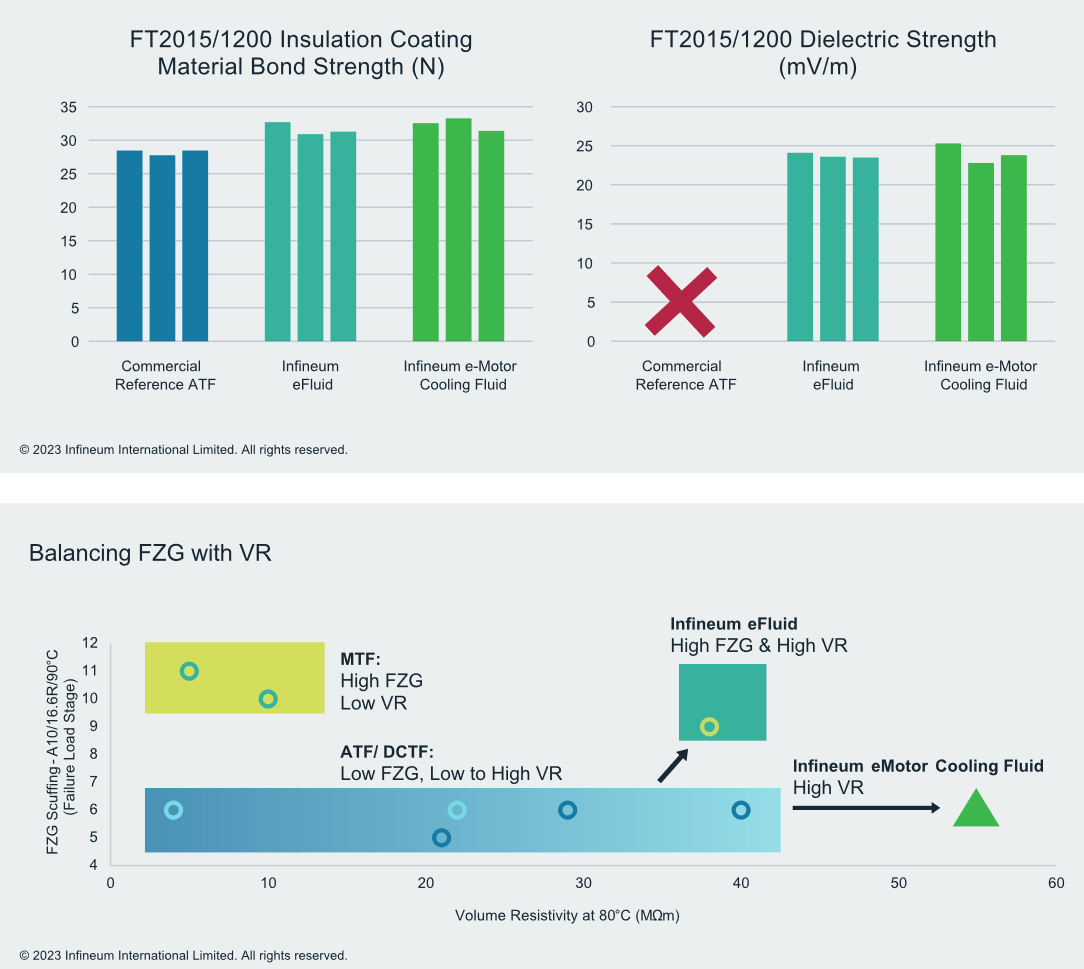

In addition, thermal shock testing is a useful way to evaluate compatibility with other materials including varnished wire and a range of insulation materials under extreme thermal cycling conditions (see visual 5).

Using these tests, Infineum’s eFluid and eMotor cooling fluid have shown outstanding motor material compatibility performance.

Electrical properties

The issue of electrical compatibility overarches all electric vehicle developments. The power electronics operate at hundreds of volts, which means the fluid needs to provide enough resistivity to avoid any current leakage and/or shortcuts.

However, if the fluid is completely insulating, it can lead to static charge buildup which can damage the equipment due to arcing phenomena. eFluids designed with optimal resistivity can help OEMs to reduce the size of the motor and casing, which means less material use, lower production costs, and enables the use of even higher voltages.

In our view, it is important to tailor eFluid formulations for commercial vehicles to ensure they deliver the right balance of performance to meet individual customer needs.

eFluids need to provide both high gear scuffing and high-volume resistivity performance, making a tailored eFluid a good fit for use in these applications (see visual 6).

Conclusion

A careful balance of additive components and base stock is needed to create tailored eFluids that deliver the required cooling, electrical performance and materials compatibility electric commercial vehicles require. But, at the same time, these complex fluids must also meet gear and bearing durability, aeration and efficiency requirements.

Infineum eFluids have demonstrated improvements in electrical performance, material compatibility and motor cooling efficiency via modelling, novel test methods, eMotor rig testing and field trials in electrified applications. As we look to a future where transmission oils in commercial vehicles will be replaced by advanced eFluids, Infineum is ready with tailored solutions that are aligned with evolving hardware designs.

Visit the Infineum exhibition stand at CTI Berlin to speak to our experts.