Ping Yu, CEO, Chief Engineer, Founder, Jing-Jin Electric

Dr. Yang Cao, Transmission Senior Supervisor, Jing-Jin Electric

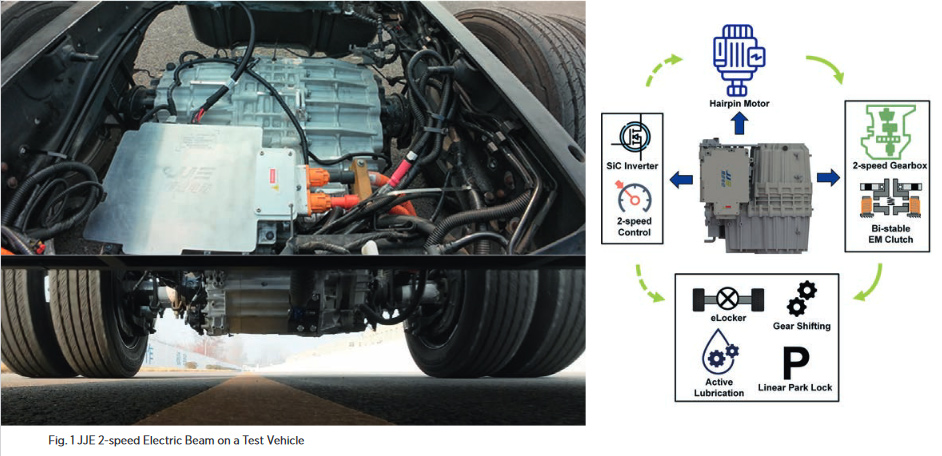

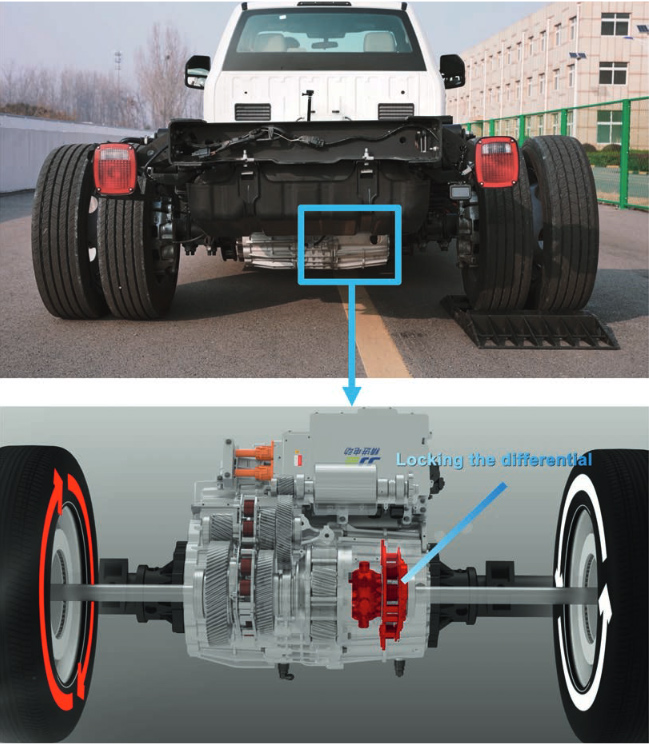

JJE’s latest innovation, a 2-speed electric beam axle that was unveiled at the 2023 CTI Berlin symposium, has recently completed vehicle testing. The tests were conducted on two trucks at the JJE China test center track and at the JJE North America facility in Farmington Hills, MI. The electric beam axle performs with strong power, uncompromised towing capacity, payload, and gradeability. It features an extremely fast, smooth, and high-quality shift, that makes it feel like a single-speed system. This electric beam axle integrates multiple advanced technologies; such as bi-stable electromagnetic clutches, a bi-directional shifting clutch, a bi-stable eLocker, a linear park lock system, and an active cooling and lubrication system, all of which have now been validated through vehicle testing. The controls for these functions have been integrated into the electric beam’s SiC inverter, as JJE’s “One-Box” control. The entire system has undergone comprehensive validation at JJE’s track- covering straight track, cross twist, cobble stone, potholes and grades.

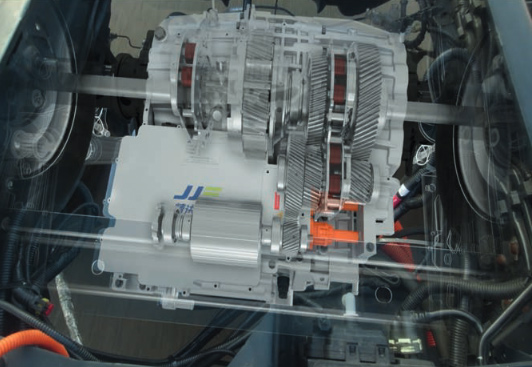

The 2-speed axle features a high efficiency hair-pin electric motor and a 400kW SiC inverter with a “safe towing” feature. It also includes an electromagnetically shifted 2-speed gearbox with a neutral position that also serves as a disconnect, a bi-stable differential eLocker, and a linear park lock system. The gearbox enables the axle to deliver up to 18,000Nm of wheel-end torque, and maximum vehicle speed exceeding 160km/h. The integrated design of the motor and gearbox reduces the axial length of the system.

Fig. 2 JJE Electric Beam at the Rear of a Truck Demonstrator

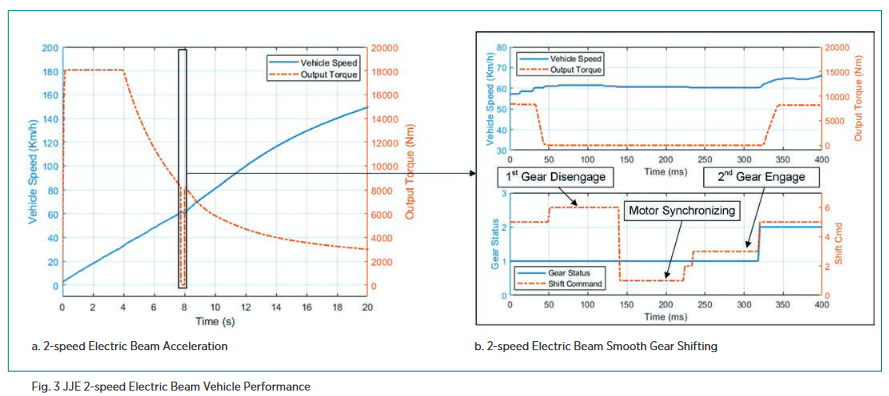

JJE’s 2-speed electric beam axle delivers high performance and high output speed that can be achieved with little power degradation at high speeds. Its efficiency spans a broad speed range and significantly outperforms single speed axles thanks to the 2-speed gearbox. During vehicle testing, the shift quality was found to be seamless, with upshifts or downshifts achieved in less than 300ms- faster and smoother than any DCT, CVT, or AT.

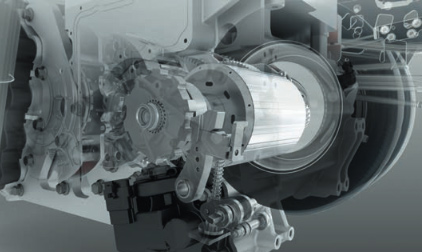

Electric Motor

JJE’s mature hairpin motor designs cover the performance requirements for a wide range of vehicles. For this electric beam axle system, the electric motor’s peak power reaches 420kW at 650Vdc, with 97.4% maximum efficiency, and over 90% of the efficiency map stays above 88%. The water & oil cooling design allows the electric motor to produce high continuous power.

2-speed Gearbox

The 2-speed gearbox provides high launch torque, high vehicle speed, and high efficiency over a broad duty of conditions and helps contain the motor’s top speed for better reliability and durability. It also broadens the high efficiency operating range, and significantly reduces thermal loading in the system at high speeds. The neutral position is a natural “disconnect.” Combining this rear axle with a neutral position and a constantly powered front eAxle, the vehicle efficiency can be improved.

JJE’s patented DirectFluxTM Bi-stable eLocker enhances the functional safety of the locker and eliminates the constant power consumption. A proven park lock system is implemented on the motor shaft, or the “lowest torque” point of the system. An oil pump provides active oil lubrication, which allows for a low oil level in the gearbox, reduces gear churning loss. All these sub-components have been fully validated on JJE’s test track.

SiC Inverter

The electric beam axle includes an 850V SiC integrated inverter, with functional safety capability up to ASIL-D level. Multiple functions, such as: motor control, differential locker control, 2-speed transmission control, and park lock control are integrated in the inverter, taking advantage of the inverter’s high functional safety control platform as a powerful “One Box” control. With a backup power supply, the inverter enables “safe towing,” a feature highly desired by end users. It is a critical safety redundancy in the event of 12V power supply loss.

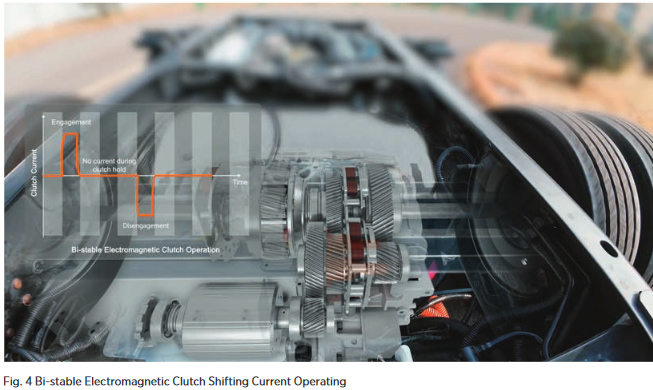

DirectFluxTM Bi-stable Electromagnetic Clutch

Patented bi-stable electromagnetic clutch is one of JJE’s most advanced technologies. It is used for gear shifting and locking the differential in the electric beam axle system. This technology has been successfully used as a differential locker in JJE’s 300kW SiC EDM and as a disconnect in JJE’s new AWD EDM.

Fig. 5 Linear Park Lock System

DirectFluxTM electromagnetic clutch takes advantage of its innovative magnetic circuit design. Compared to the more conventional reluctance flux magnetic circuit design, the DirectFluxTM design greatly reduces flux leakage, and therefore, utilizes magnetic flux more effectively to generate force. The conventional reluctance flux design cannot avoid magnetization of parts near flux circuit, or “flux leakage”, which causes less effective utilization of magnetic flux. As a result, DirectFlux acts 2-3 times faster than a reluctance flux design.

The bi-stable clutch is inherently fail-safe as it won’t change state in the event of loss of power. This feature gives the bi-stable clutch a higher safety level than a mono-stable clutch. For the differential locker, it will prevent sudden locker release due to the loss of power or control failures. For the transmission shift, it will prevent unexpected gear shift back to neutral which could lead to the vehicle loss of traction. On energy consumption aspect, the bi-stable clutch’s feature of “zero holding current” eliminates the need for a holding current and, in turn, achieves zero constant power consumption.

In the development stage of the electromagnetic clutch, a software platform based on several simulation tools is built for precise simulation result. This platform covers signal, electric, electromagnetic, and mechanical aspects. It addresses almost every detail, including software control, PCB layout, electromagnetic transient simulations, multi-body dynamic simulations, and strength, providing strong support to the clutch’s development.

Electric beam axles are designed for pickup trucks, light-duty trucks, or medium-duty trucks. The vehicle test of the electric beam further reinforces the advantages of electric beam axle utilization and gains confidence in the roadmap of trucks electrification. JJE takes advantage of its experience, knowledge, and know-how in electric drive, strong R&D capabilities on motor, inverter, transmission and clutches and expertise in system integration, creating a 2-speed electric beam axle for the large medium truck segment.

Fig.6 JJE DirectFluxTM Bi-Stable Electromagnetic Differential Locker