Electrified Beam Axles for Light Commercial Vehicles

Industry studies have shown the benefits of battery electric vehicles (BEV) for short haul commercial applications, focused on the reduced total cost of ownership versus ICE vehicles, yet the shift to Light Commercial Vehicle (LCV) BEV’s has been slow. What is holding back the transition? There are many factors including lack of charging infrastructure, long term service unknowns, and range anxiety. These concerns can make it difficult to justify the purchase price of a LCV BEV, especially when the current vehicles have not been optimized.

Many initial BEV offerings in the LCV market are built on ICE platforms with design trade-offs made to expedite the time-to-market. These trade-offs, such as independent drive axles and a DeDion suspension, often reduce load capacity, decrease efficiency, and increase cost.

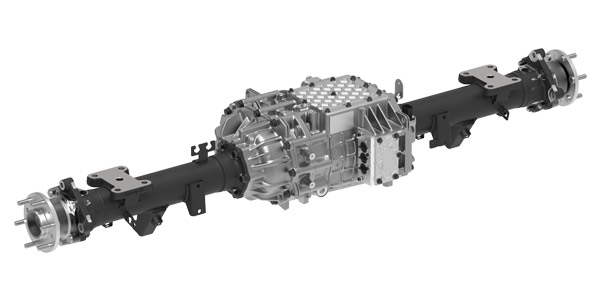

The solution to these trade-offs is the electric beam axle (eBeam). An eBeam can be implemented with leaf springs to maximize payload or with a multi-link suspension for improved ride and handling. Both arrangements increase the vehicle capacities and reduce the vehicle’s bill of material cost when compared to an independent drive axle with half-shafts and an independent suspension or a DeDion tube.

As the global leader in Class 1-3 beam axles with a rising portfolio in electrification, AAM has the product building blocks in place to support the expanding market of electrified light commercial vehicles.

Author:

Martin Burgbacher

Executive Director – Engineering

American Axle & Manufacturing

martin.burgbacher@aam.com