DI (FH) Wilhelm Vallant, Product and Business Development Manager Transmission & E-axle, AVL List GmbH

The automotive sector is experiencing a profound transformation towards electrification, motivated by the dual objectives of mitigating greenhouse gas emissions and ensuring uncompromised vehicle performance. Original Equipment Manufacturers (OEMs) are increasingly challenged to meet rigorous sustainability and cost-efficiency benchmarks. In response, AVL introduces a forward thinking and validated solution that establishes new standards in electric drive unit (EDU) efficiency, lifecycle CO2 emissions reduction, and system integration.

This article details the development and empirical validation of a high-efficiency EDU system that achieves an average cycle efficiency exceeding 94 % under the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) as well as the China Light-Duty Vehicle Test Cycle (CLTC) and maintains vehicle energy consumption below 10 kWh per 100 km. The discussion further encompasses the technological advancements and sustainability frameworks that underpin these accomplishments.

EDU Architecture and Operational Strategy

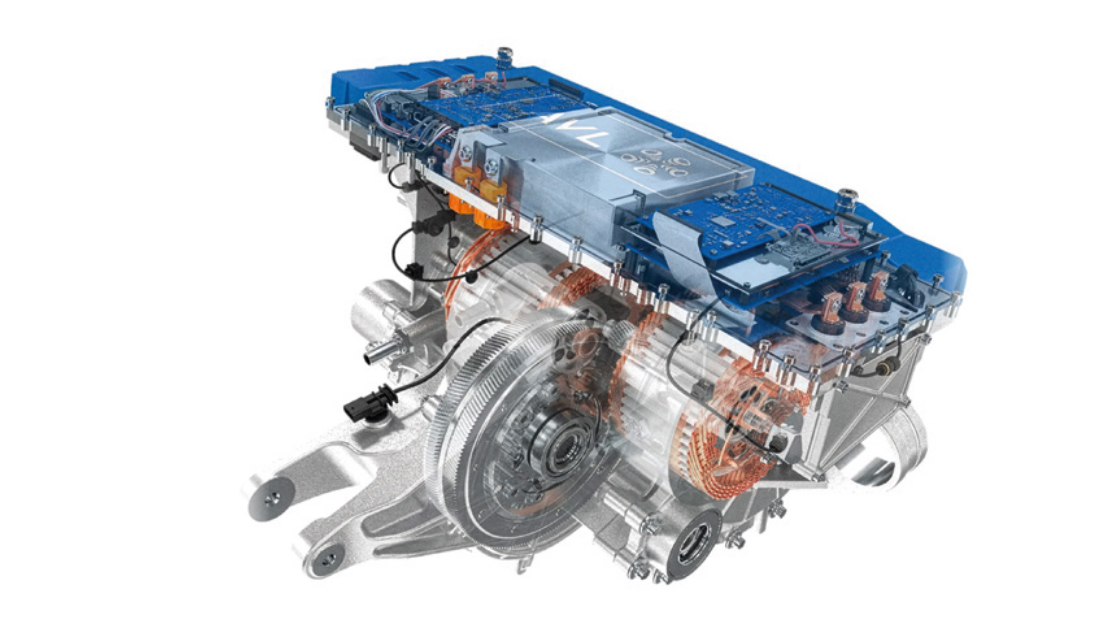

At the core of a demonstrator vehicle developed by AVL as part of an R&D project lies a dual-motor EDU configuration consisting of:

- Two Permanent Magnet Synchronous Machines (PMSMs)

- A compact, single-stage spur-gear transmission with double helical gears

- Compact final drive with integrated planetary gear differential

- A dual Silicon Carbide (SiC) inverter system

- Oil catch tank to decrease the oil level during operation

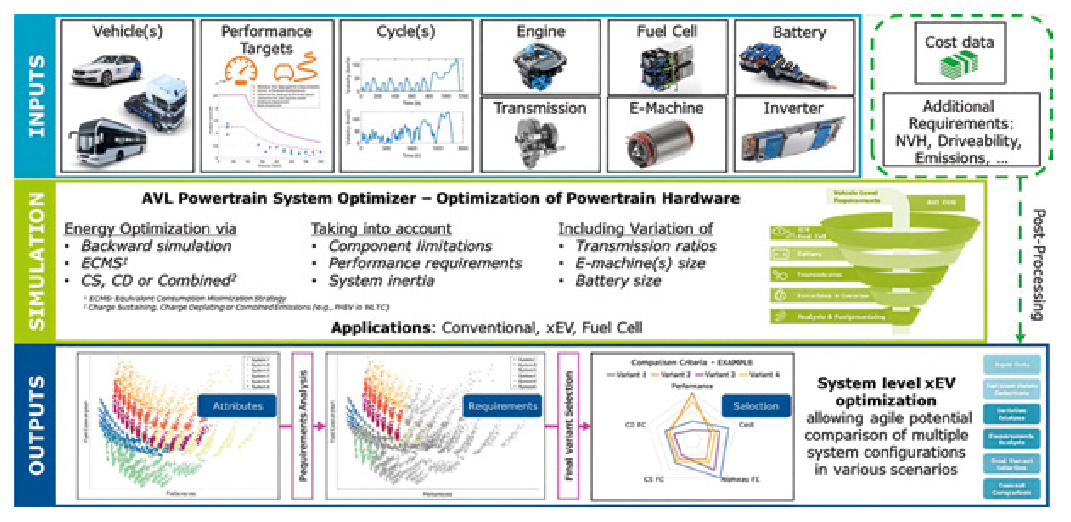

o meet the ambitious energy consumption and efficiency goals, an innovation-driven development process was implemented, enabling the early-stage comparison of a wide range of technologies. By applying advanced simulation methods, numerous potential solutions can be evaluated early on in terms of their alignment with the project objectives. Key measures include component technology selection, architectural studies to balance performance and losses and system simulation using AVL’s proprietary development toolchain, the Powertrain System Optimizer (PSO). Step by step, the number of possible variants is reduced by selecting the most promising solutions, while the level of simulation detail is progressively increased. Once only a few options remain, detailed component optimization and initial control strategy refinement are carried out in the final development phase. FIGURE 1 illustrates the AVL PSO methodology.

Figure 1: AVL Powertrain System Optimizer Workflow

The selection of transmission, electric motor and inverter technologies was guided by cost reduction and sustainability, with a focus on intelligent integration, minimizing drag losses and using efficient materials. Achieving maximum efficiency in the EDU architecture was essential to reaching a WLTP cycle efficiency of more than 94 %, and a dual-motor concept proved to be the most effective solution. The main motor was designed for efficient continuous operation, while the secondary motor supports boosting and recuperation. This secondary motor, which can be decoupled via a dog clutch, was specifically optimized for its intended use and the load points defined by the operating strategy.

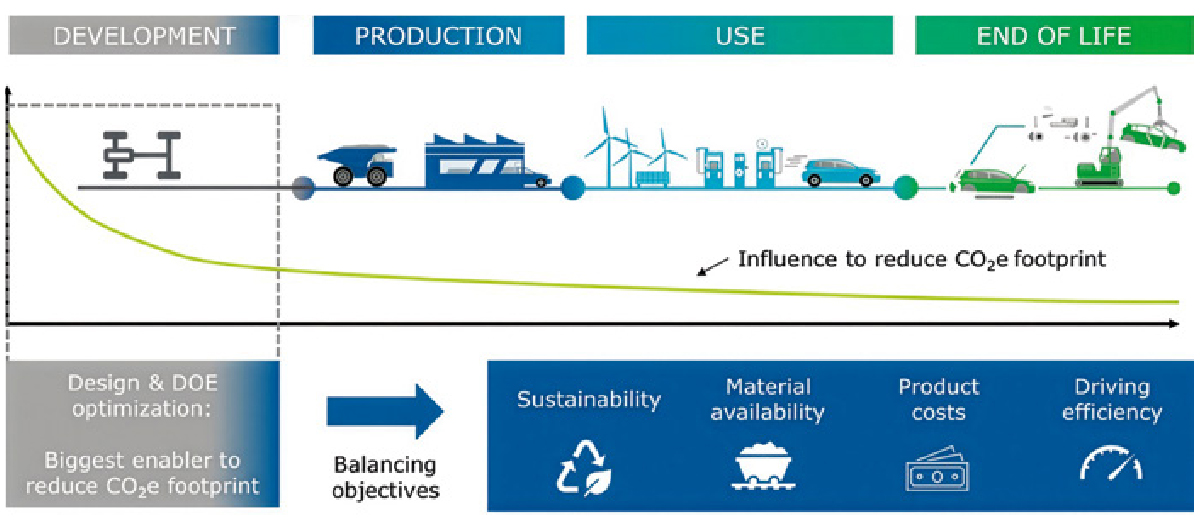

Figure 2: Sustainability in the Drivetrain – Impact of Development Phase on Lifecycle GHG Emissions

The AVL PSO development methodology was used to optimize the EDU’s dimensions, simulating numerous variants to evaluate efficiency and performance under varying parameters. The basic design specification was derived from system simulations, with components and operating strategies already optimized during the early concept phase.

Outcome of this design evolution process is a unique system featuring key elements to support the lowest possible energy consumption in the vehicle. The gear-set features a single stage transmission with double helix gears, reducing mechanical losses in high torque and speed operating conditions by -16 % compared to conventional designs. In moderate torque and speed losses are reduced by 11 %. To enable compact packaging of the two e-Motors a planetary differential is used which could be packaged inside the double helix final drive gear with an axial length of less than 80 mm. The lightweight design reduces weight by -15 % to -20 % compared to conventional solutions.

An oil catch tank is positioned at the differential gear to collect oil effectively. This collected oil is then distributed to various components, including gears, bearings, and the dog clutch. Besides securing proper lubrication of the system the oil catch tank also lowers the oil level in the transmission sump, thus reducing splash-losses while the vehicle is running. The key element for enabling the operation of the boost electric motor is an electromechanically actuated disconnect clutch located on the e-Motor shaft. When it is not engaged, it is ensuring

operational efficiency.

To ensure safe operation of the dog clutch a special simulation experiment was set up to analyze the impact of the stator windings magnetic field on the dog clutch’s actuation force. Based on this investigation, using the advanced in-house simulation capabilities, it was possible in a virtual stage to evaluate a safe operation of the dog clutch under all operating conditions.

With introduction of the disconnect clutch enabled the implementation of an operating strategy, further contributing to highest possible system efficiency hence contributing to lowest possible energy consumption.

Design-to-CO2 Methodology

Considering the complete life cycle as a system with certain limits is essential for a valid analysis. Automotive manufacturers can influence most scope 1 and 2 emissions according to the Greenhouse Gas (GHG) Protocol Corporate Standard (2) and have certain but not full control of the upstream scope 3 emissions of the supply chain, as well as the scope 3 emissions downstream in the usage and recycling phases (3).

In product life cycle modelling, it is important to know the qualitative patterns for CO 2 e influenceability, determination and the actual occurrence to define appropriate optimization measures at the right times.

FIGURE 2 shows an ideal-typical pattern for the product life cycle of a Battery Electric Vehicle (BEV) assuming a European 2023 electricity mix in the production and in-use phase (1). It is shown that the CO 2 e influenceability decreases significantly during the later phases described. Although the majority of CO 2 e emissions occur during the production phase and typically need to be offset during the in-use phase when compared to other powertrain technologies, the development phase has the most significant impact on the CO 2 e footprint.

By integrating life cycle assessment (LCA) methodologies and sustainability criteria from the outset, developers can evaluate and compare the environmental impacts of various powertrain technologies. This proactive approach enables the identification of technologies that not only meet performance and cost requirements but also minimize CO 2 e emissions throughout the product’s life cycle. Consequently, making informed decisions early in the development process ensures that the chosen technology aligns with sustainability goals, leading to a more environmentally friendly product.

Through the integration of these cutting-edge technologies, AVL enables OEMs to deliver electric powertrains that excel in performance, efficiency, and sustainability. This advancement constitutes a significant milestone toward fulfilling the automotive industry’s climate objectives while preserving competitive product offerings.

Real Life Demonstrator

From the outset, the goal was to transfer the resulting technology into customer applications, aiming for comparable efficiency and consumption values in the target vehicle. When the EDU was integrated into a customer vehicle based on the original design, a slight efficiency loss was initially observed due to different driving conditions and load points. However, the efficiency still significantly improved the customer’s baseline EDU. To meet the original efficiency targets, goal-oriented adjustments were necessary. Subsequently, the electric motor topologies and gear ratios were optimized. The adaptation process included detailed investigations to improve efficiency under the boundary of materials usage comparable to benchmark solutions. All modifications were made with the updated customer load profile and the geometric constraints of the target vehicle in mind, ensuring seamless integration. Vehicle simulations confirmed the effectiveness of these measures, achieving an average customer cycle efficiency of more than 94 %.

The EDU was tested both on a test bench and in the vehicle to validate system efficiency. While the test bench results did not exceed the 94 % cycle efficiency target, further optimization of the operating strategy for in-vehicle use led to an average efficiency of 94.4 % during real-world testing, confirming the achievement of the project goals.

Conclusion

AVL has developed a high-efficiency electric drive unit (EDU) achieving over 94 % cycle efficiency under WLTP and CLTC standards, with vehicle energy consumption below 10 kWh/100 km. The EDU features a dual-motor configuration with permanent magnet synchronous machines, a single-stage double helical gears transmission, and a dual SiC inverter system, optimized through AVL’s Powertrain System Optimizer. Innovations include a lightweight, compact design with reduced mechanical losses and an electromechanically actuated disconnect clutch to enhance efficiency. The development incorporated lifecycle CO₂ assessments to align with sustainability goals, emphasizing early-stage optimization to minimize emissions. Real-world vehicle integration confirmed the system‘s efficiency, reaching 94.4 % in testing, demonstrating a significant advancement in electric powertrain performance and environmental impact reduction enabled thorough AVL technology and engineering methodology.

Validated Outcomes:

- Achieved an average EDU efficiency of more than 94 % in real-world testing scenarios

- Recorded 94.4 % efficiency in customer-specific driving cycles

Quotes:

- „>94 % EDU efficiency and <10 kWh/100 km energy demand – validated on the road, not just in simulation.“

- „Design-to-CO2e turns sustainability into an engineering parameter, not a marketing claim.“