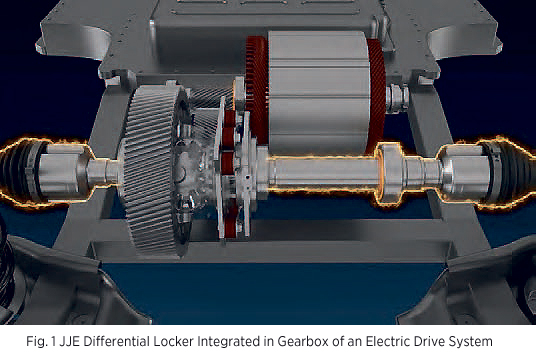

Differential locker locks up differential to ensure torque output on vehicle’s wheel under low traction conditions. the axles together to provide 100% of available torque to the wheel with traction. At 2022 CTI US, JJE debuted its mono-stable and bi-stable DirectFlux differential locker (eLocker). Now this eLocker has been equipped by mid- and full-size SUVs, pickup trucks, and off-road vehicles. JJE eLocker features compact size, high torque, and high engagement speed. JJE has achieved maximum 18,000Nm locking torque in JJE’s 2-speed electric beam axle. Depending on vehicle requirement, JJE’s eLocker can be bi-stable, which is fail-safe (prevent sudden locker release and loss of traction); or can be mono-stable to achieve “default to open” function.

Ping Yu, CEO, Chief Engineer, Founder, Jing-Jin Electric

Dr Yang Cao, Transmission Clutch Team Manager, Jing-Jin Electric

DirectFluxTM electromagnetic clutch makes locking faster and safer

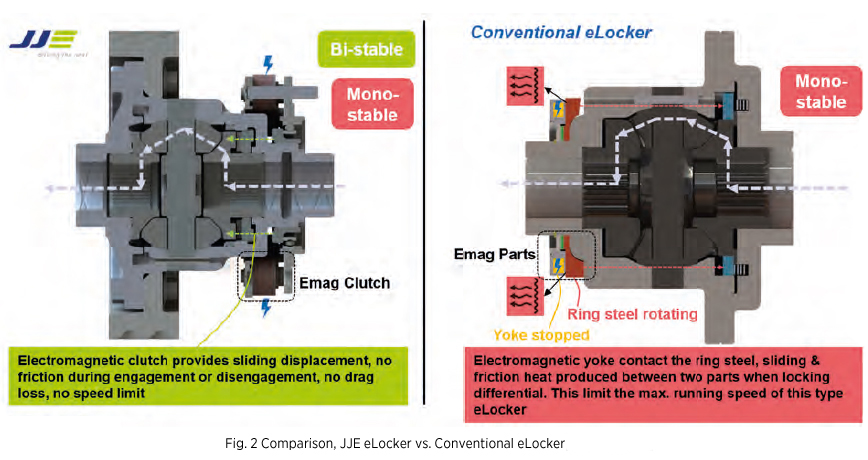

DirectFluxTM electromagnetic technology clutch is used to drive the locker. The clutch uses direct magnetic force, or magneticflux in the same direction as the magnetic force. JJE created unique magnetic circuit that greatly reduces flux leakage, hence utilizes the magnetic flux to generate force more effectively, generating higher electromagnetic force than conventional reluctance clutches. With the DirectFluxTM electromagnetic technology clutch, eLocker can be designed as mono-stable or bi-stable based on vehicle requirement. A mono-stable eLocker is locked by magnetic force generated by current, and is unlocked by spring force when the current is turned off. A bi-stable eLocker will only change its state when there’s an affirmative current command, which is only a pulse; otherwise, it will hold its state.

DirectFluxTM electromagnetic technology clutch is used to drive the locker. The clutch uses direct magnetic force, or magneticflux in the same direction as the magnetic force. JJE created unique magnetic circuit that greatly reduces flux leakage, hence utilizes the magnetic flux to generate force more effectively, generating higher electromagnetic force than conventional reluctance clutches. With the DirectFluxTM electromagnetic technology clutch, eLocker can be designed as mono-stable or bi-stable based on vehicle requirement. A mono-stable eLocker is locked by magnetic force generated by current, and is unlocked by spring force when the current is turned off. A bi-stable eLocker will only change its state when there’s an affirmative current command, which is only a pulse; otherwise, it will hold its state.

Normally, bi-stable differential locker provides higher safety level, as it won’t change state in the event of loss of control. This fail-safe feature can prevent sudden locker release due to control failure. This security enhancement is valuable for rear axle, or the “main drive axle”, for conditions such as claiming steep rock trail or pulling heavy boat out of water on slippery ramp. While for front steerable axle, mono-stable differential locker is sometimes preferred as it will default to open position in the event of control failure, which unlocks the front differential to allow easier steering at higher speed.

No speed limit, no drag loss

Conventional locking differential must limit vehicle speed very low for engagement, and also limit vehicle’s running speed after engagement. “The locker engagement should not be maintained greater than 30kph”, or “the locker only can be engaged when vehicle speed is below 5kph”. The operating speed is limited by the rotational friction between differential case and electromagnetic coil case during locker’s engagment. And the conventional locker can only be mono-stable.

Conventional locking differential must limit vehicle speed very low for engagement, and also limit vehicle’s running speed after engagement. “The locker engagement should not be maintained greater than 30kph”, or “the locker only can be engaged when vehicle speed is below 5kph”. The operating speed is limited by the rotational friction between differential case and electromagnetic coil case during locker’s engagment. And the conventional locker can only be mono-stable.

JJE’s eLocker is driven by DirectFluxTM electromagnetic clutch, which has no contact or friction between moving plate and coil assembly during engagement and disengagement. Therefore, there is no mechanical wear, no drag loss, no heat generation. Therefore, JJE eLoker does not limit speed for engagement or operation.

Wide application

Differential locker is indispensable in off-road vehicles, and other high capability vehicles such as heavy duty pick-up trucks JJE’s eLocker has been used in several independent axle 3-in-1 drive units, with output torque ranging from 3000Nm to 6,000Nm. The differential locker is also adopted in JJE’s 18,000Nm electric beam axle. JJE eLocker does not limit operating speed, which enhances these vehicles’ capabilities when both locking and speed are needed, e.g., driving through sand or mud.

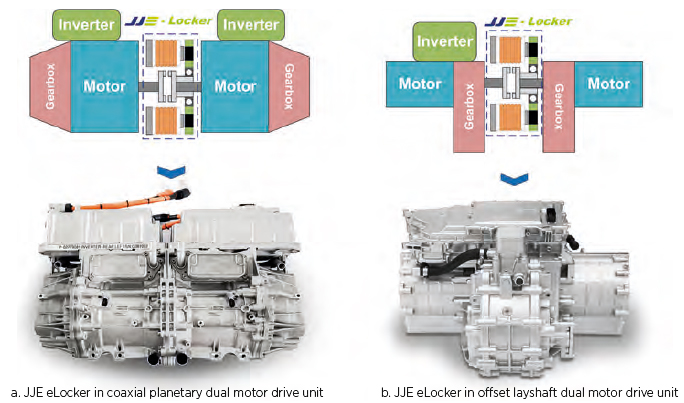

JJE eLocker for back-to-back dual motor drive

Back-to-back dual motor e-drive does not require a differential, but some vehicles do require a locker that mechanically locks up left and right wheels. JJE’s electromagnetic clutch is suited for such locker function. JJE has two back-to-back dual motor drive units – coaxial planetary and offset layshaft – and both drive units use bi-stable electromagnetic clutch as locker.

Fig. 4 JJE’s eLocker for back-to-back dual motor drive unit

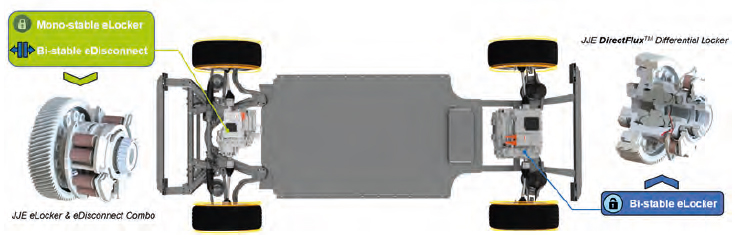

JJE eLocker & eDisconnect combo system

JJE eLocker can also be integrated with JJE eDisconnect, which becomes a compact disconnect & locker combo. This combo is most valued for secondary drive axle, where disconnect is used for changing configuration between 4×4 and 4×2, and locker is used for traction assurance. As example, a 4×4 off-road SUV needs such flexibility.

The eLocker-eDisconnect Combo packages nearly the same as JJE’s single eLocker, thanks to the deeply integrated mechanical design and very its compact electromagnetic elements. This new Combo product will be launched in a high-end off-road SUV in 2025.

Fig. 5 eLocker & eDisconnect solution for high-end off-road SUV

eDrive application rapidly expands and now reaches almost all market segments. Users accept no compromise in vehicle’s capability, and even expect more from eDrive than ICE. JJE eLocker, eDisconnect and the Combo are designed to meet such high market expectations, and will continue to push out the envelope of technology.