Johannes Becker, Dive Engineering Software, Inc.

Felix Pause, dive solutions GmbH

Drivetrain electrification across the automotive and commercial vehicle industry drives increasingly power-dense electric motor designs, which require well-engineered cooling systems. Front-loading e-motor thermal simulations in the early design stage can de-risk prototypes and unlock more innovative designs.

The Role of Smoothed-Particle Hydrodynamics in Drivetrain Development

As the automotive industry is shifting towards electrification, the design of electric motors is key for optimizing vehicle performance. Balancing increased power and longevity with compactness and simplicity necessitates the use of sophisticated cooling strategies to maintain optimal operating temperatures. Various simulation methods have been explored in the past, ranging from traditional Volume of Fluid (VOF) techniques to particle-based approaches.

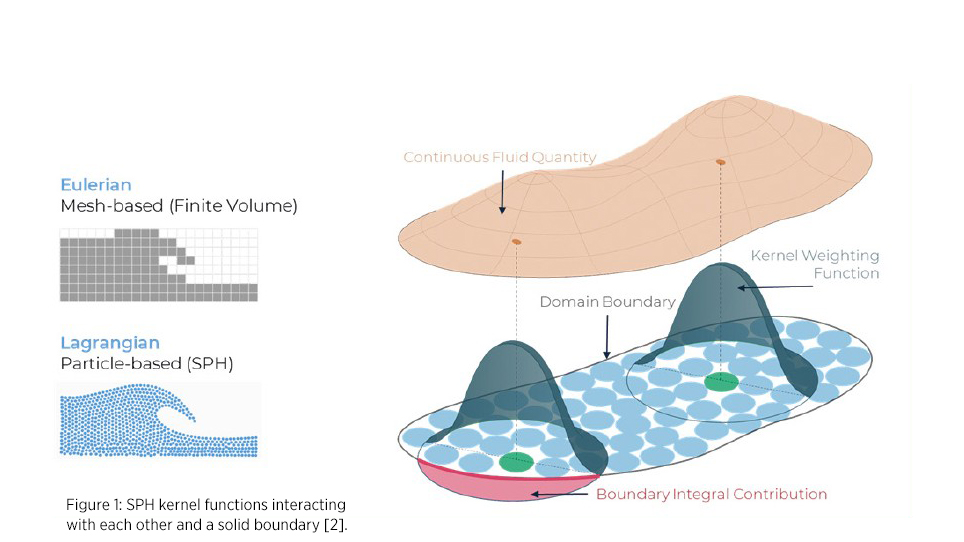

In response to increasing market pressure for faster, more efficient product development under constrained resources, Smoothed Particle Hydrodynamics (SPH) offers a flexible and powerful simulation approach, particularly suited for early-stage design. Unlike traditional CFD, SPH − as the name suggests − simulates fluids as a collection of small particles and does not require mesh generation (see Figure 1). This provides significant pre-processing and numerical efficiencies in cases where mesh generation and remeshing are a bottleneck in VOF methods, allowing engineers to explore large numbers of design variations quickly and cost-effectively. For that reason, SPH has become a widely used method of analyzing lubrication and cooling performance in drivetrain engineering, due to its ability to accurately model free surface and multiphase flows, as well as its efficacy in handling complex geometries and moving components. Consequently, SPH is increasingly applied in the design of electric motors as well.

Modeling Heat Transfer in Complex Geometries with SPH

Correctly predicting cooling performance in simulation fundamentally requires accurate modeling of surface wetting by the coolant, i.e. a good surface tension model, and consideration of the (often significant) temperature-sensitive viscosity of coolant oils [1]. SPH enables detailed simulation of how coolant oil absorbs and transfers heat across complex geometries like coil windings, accounting for temperature-dependent viscosity layers. By applying adaptive particle refinement [2] and realistic boundary conditions, SPH captures both transient and steady-state heat transfer behaviors. This allows engineers to evaluate heat transfer coefficients, optimize cooling strategies, and support thermal network models − especially in areas where empirical data is lacking.

This article presents findings from simulations of a simplified, actively cooled e-motor employing SPH. The results are validated against experimental data, demonstrating the method’s efficacy in predicting oil dynamics and heat transfer.

Experimental Reference and Simulation Setup

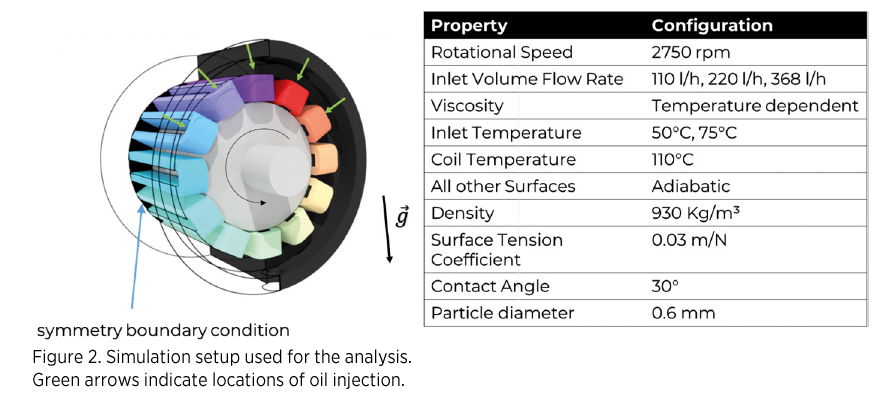

To validate the applicability of SPH in real-world designs, we examined an experimental e-motor cooling case by Davin et al. [3] as our reference scenario. Davin et al. investigated a 40kW radial flux machine equipped with 12 coils and examined different cooling configurations. Here, we focus on investigating a setup utilizing 5 inlets to distribute oil onto the coil windings. Since the experimental setup is symmetrical, our simulation model encompasses only half of the domain, with symmetry boundary conditions applied to the center plane. The setup is illustrated in Figure 2.

To validate the method against the experimental references, the inlet mass flows and inlet temperature of the coolant are varied. Since the properties of the coolant oil were not reported in the original work, some assumptions had to be made. As viscosity was given at 50 and 75°C, the following exponential law was used to interpolate between these two points and account for the influence of reduced viscosity with increasing temperature:

![]()

The density, thermal conductivity, specific heat capacity, surface tension coefficient and contact angles of the coolant used in the experimental work were not reported. Thus, typical values for coolant oils were applied (see Figure 2).

Results

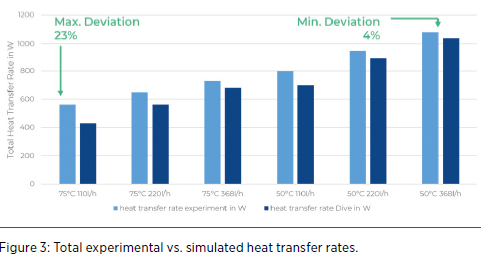

For each of the six operating points, the heat flow rates on the coils are obtained and compared with the experimental results. The simulation generally follows the experimental trend in [3] of increasing heat transfer rates with increasing volume flow rates and decreasing inlet temperatures. Moreover, a 77 % to 96 % match with experimental reference is found for the 6 operating points (see Figure 3). Given the accuracy of an experiment and the assumptions made, this indicates that the simulation can capture the complex multiphase flow present in the e-motor.

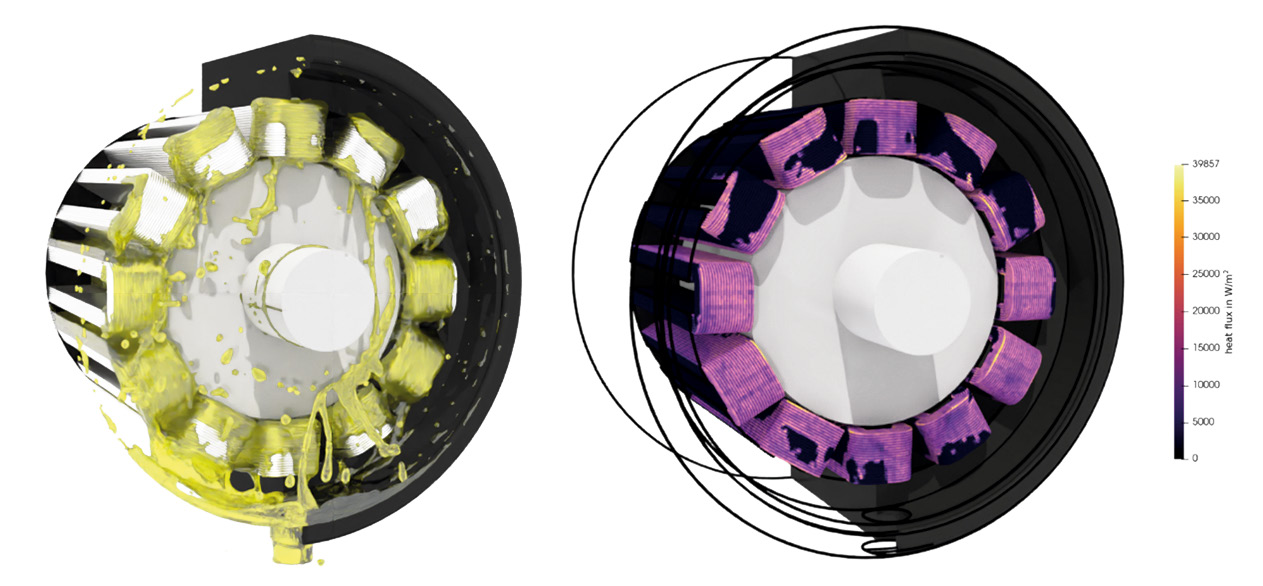

The method can therefore be used to test different design variations. In Figure 4, a snapshot of oil distribution predicted by the simulation is given. Here, the oil flow could be optimized by changing the nozzle position or design, ensuring that all coils are adequately cooled.

Figure 4: Oil distribution and heat flux at 368 l/h and 75°C.

Conclusions

The Smoothed-Particle Hydrodynamics method is widely applied and extensively validated in different sectors and applications. I can reliably predict complex multiphase flows in drivetrain, automotive, manufacturing, and more. Our results show accurately predicted heat transfer in the e-motor case, with deviations from experimental data ranging from 4 to 23 %.

Initial setup time was around 2 − 3 hours and only minutes for every additional operating point, the computational effort for each operating point was around 3 − 6 hours. By integrating SPH within a scalable, cloud-based platform, conducting extensive parametric studies, such as testing different nozzle types, orientations, placements, and coolant flow rates, can be parallelized. Automated DoE configuration and parallel execution of simulation and data analysis (i.e., simulating all operating points in parallel) allow for rapid design space exploration [4] − enabling engineers to investigate the effect of nozzle types, positions, inlet conditions (temperature/flow rate) or other design changes with same-day turnaround.

As the automotive industry accelerates toward more compact, powerdense electric drivetrains, SPH offers a critical simulation tool to meet thermal management challenges early in the design cycle − supporting faster innovation, reduced prototyping costs, and more robust e-motor designs.

Sources:

[1] G. A. Mensah, P. Sabrowski, and T. B. Wybranietz, “Practical guidelines on modelling electric engine cooling with SPH,” in 2023 International SPHERIC Workshop, 2023.[2] B. Legrady, “Particle-Based CFD Study of Lubrication in Power Transmission Systems Using Local Refinement Techniques,” Power Transmission Engineering,

vol. February 2024, 2024.

[3] T. Davin, J. Pellé, S. Harmand, and R. Yu, “Experimental study of oil cooling systems for electric motors,” Applied Thermal Engineering, vol. 75, pp. 1–13, 2015.

[4] B. Legrady, “Efficient Numerical Assessment of Thermal Effects in a Gearbox Using Smoothed Particle Hydrodynamics,” in American Gear Manufacturers Association,

in Fall Technical Meeting, vol. 24FTM25, 2024.