Team Brudeli Green Mobility

The heavy-duty trucking industry faces significant challenges in reducing emissions and meeting increasingly stringent regulations. With medium and heavy-duty trucks contributing approximately 5% of global carbon emissions, there is an urgent need for innovative solutions beyond the fully electric vehicles. Brudeli Green Mobility (Brudeli) has developed and tested the Brudeli Powerhybrid™, a plug-in hybrid powertrain technology that promises to accelerate electrification in these hard-to-abate sectors.

Technical approach and configuration advantages

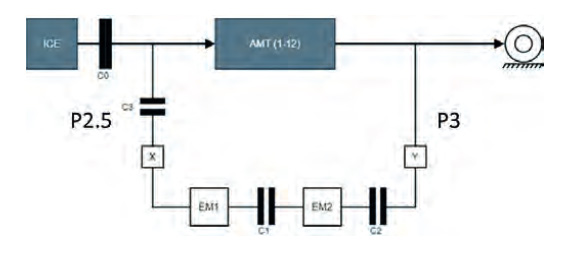

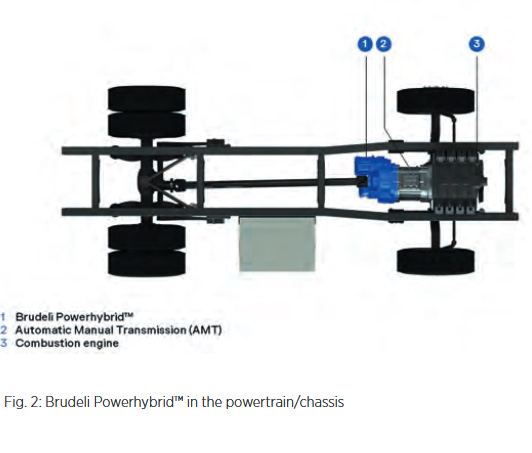

The Brudeli Powerhybrid TM utilizes a P2.5/3 configuration (figure 1), a sophisticated plug-in hybrid system designed specifically for heavy-duty trucks. This configuration integrates two electric motors into the transmission.

The Brudeli Powerhybrid TM utilizes a P2.5/3 configuration (figure 1), a sophisticated plug-in hybrid system designed specifically for heavy-duty trucks. This configuration integrates two electric motors into the transmission.

The P2.5/3 design offers several key advantages over the more common P2 configuration. Its flexible power management through a dual-motor setup allows for both parallel and serial hybrid modes, optimizing efficiency across various driving conditions. In serial mode, efficiency is improved as one motor can generate electricity while the other drives the wheels, particularly enhancing performance in low-speed or stop-and-go traffic. The enhanced powershift capability, achieved through integration within the transmission, enables smoother gear changes without power interruption, improving driving comfort and energy management during acceleration and deceleration.

Fig. 1: Schematic overview of the Brudeli Powerhybrid™ patented concept.

ICE – Internal Combustion Engine,

AMT – Automated Manual Transmission,

C – Clutches, X – Input fixed gear,

Y – Output fixed gear,

EM1/EM2 – electric motors.

The new principle makes it possible to drive the vehicle entirely electrically. Two electric motors are controlled and will act as a mechanical gearbox. In our concept, this is arranged by electric motor 1 (EM1) being permanently connected to the input gearbox shaft (AMT – Automated Manual Transmission), while electric motor 2 (EM2) is alternately connected to E1 or, during gear changes, connected to the output gearbox shaft.

Higher electric power potential is achieved through the dual-motor design, which can deliver more electric power and higher power density than a single P2 motor, enhancing performance in electric-only mode. The system features seamless AMT (Automated Manual Transmission) integration, as being integrated into the transmission allows it to work optimally with the AMT for precise gear shifts and power delivery. Advanced regenerative braking is achieved through eMotors positioned at two drivetrain points, allowing for more efficient energy recuperation during braking.

Key technical features of the Brudeli Powerhybrid TM include:

- Dual electric motor design (2 x electric motors, totally 429 kW, 800V)

- Advanced Powershift capability for seamless gear changes

- Integrated electric power takeoff for auxiliary systems

- Power takeout could also run mechanical from ICE engine

- Compatibility with existing diesel, gas, and hydrogen drivetrains

- Real-time route optimization and energy management

Methodology and development

Brudeli’s development approach is focused on maximizing energy efficiency and flexibility while minimizing costs. The company conducted simulations and is performing real-world tests to optimize the system for various driving scenarios.

Although novel at system level, each functional element can be seen as established and mature technology, allowing for optimized time to market. Furthermore, the modular and scalable architecture – the external electric motors make a key element – enables scaling of system cost and performance per use case.

A target area of innovation at Brudeli is the real-time route optimization, accounting for factors such as geography, topography, traffic conditions, and available charging infrastructure. In a driving plan, continuously the driving modes and gear shifts are optimized to maximize efficiency. Clearly, energy efficiency and emission can be traded vs cost and time.

The development process also prioritized compliance with upcoming regulations. The Brudeli PowerhybridTM system is designed to meet the EU’s VECTO standards for 2024 and beyond, as well as the US EPA Phase 3 and California’s Advanced Clean Fleets (ACF) regulations. Furthermore, the flexible configuration is optimal for meeting future, more stringent regulations.

Results and innovation

The Brudeli Powerhybrid™ demonstrates several significant advantages over conventional powertrains and competing electrification technologies:

- Up to 80% electric driving capability, reducing diesel consumption and emissions proportionally

- Lower total cost of ownership compared to both conventional diesel and fully electric trucks for long-haul routes

- Flexible operation, allowing trucks to complete all routes without range limitations

- Smaller battery (200-400 kWh) requirements compared to fully electric trucks, reducing upfront costs

- Electric driving and leading cost without the need for Higher Power charging infrastructure

- Superior CO 2 abatement cost-effectiveness, performing on par with battery electric technology in standard drive cycles

Brudeli’s analysis shows that for a typical long-haul route of 480 km per day, the Powerhybrid™ system achieves a carbon abatement cost of 644 EUR/ton CO 2 , comparable to 602 EUR/ton for battery electric and significantly better than other alternatives like hydrogen fuel cells (1514 EUR/ton) or standard hybrids (3007 EUR/ton). If including compensation for cost factors such as charging infrastructure, vehicle availability, and payload, this would skew such analysis further toward the Powerhybrid™.

Market impact and future outlook

The Brudeli Powerhybrid™ addresses a critical gap in the electrification of heavy-duty trucking. While battery electric vehicles are making inroads in short-haul and urban applications, long-haul and heavy-duty segments remain challenging to electrify due to range and infrastructure limitations. Total addressable market of heavy- and medium duty trucks worldwide is 4.3 million vehicles. Brudeli projects that by 2050, nearly all diesel and alternative fuel trucks, including hydrogen-powered vehicles, will incorporate plug-in hybrid technology. This transition is driven by both economic factors and regulatory pressures, with new EU targets calling for a 45% reduction in heavy-duty vehicle emissions by 2030 and 90% by 2040.

The Brudeli Powerhybrid™ addresses a critical gap in the electrification of heavy-duty trucking. While battery electric vehicles are making inroads in short-haul and urban applications, long-haul and heavy-duty segments remain challenging to electrify due to range and infrastructure limitations. Total addressable market of heavy- and medium duty trucks worldwide is 4.3 million vehicles. Brudeli projects that by 2050, nearly all diesel and alternative fuel trucks, including hydrogen-powered vehicles, will incorporate plug-in hybrid technology. This transition is driven by both economic factors and regulatory pressures, with new EU targets calling for a 45% reduction in heavy-duty vehicle emissions by 2030 and 90% by 2040.

The Brudeli PowerhybridTM system’s flexibility and compatibility with various fuel types position it as a „future-proof“ solution. As charging infrastructure expands and green electricity becomes more prevalent, hybrid trucks can progressively increase their electric driving percentage, further improving their environmental performance.

Conclusion

The Brudeli Powerhybrid TM , with its advanced P2.5/3 configuration, represents a significant innovation in heavy-duty truck electrification. By offering a flexible, efficient, and cost-effective solution that can be implemented across existing fleets and routes, it has the potential to accelerate emission reduction in a sector that has proven difficult to decarbonize. The system’s sophisticated power management, enhanced efficiency, and the compatibility with various drivetrains make it a compelling option for manufacturers and fleet operators looking to meet increasingly stringent emissions regulations while maintaining operational flexibility.

As the transportation industry continues its transition towards sustainability, technologies like the Brudeli Powerhybrid™ will play a crucial role in the gap between conventional powertrains and fully electric solutions, paving the way for a more sustainable future in heavy-duty trucking.

Fig. 3: Brudeli Powerhybrid™ MK1 exhibition model shown at ACT Expo 2024 and IAA Transportation 2024

References

[1] Statista, 1.8 GtCO2 of 37.15 GtCO2.

[2] Statista (https://www.statista.com/outlook/mmo/commercial-vehicles/trucks/worldwide#unit-sales)

[3] 2050 projection: BEV 59%, IEA „Net zero by 2050” https://www.iea.org/reports/net-zero-by-2050

PHEV: Projection based on dialog/inside from OE. Volume production from 2028