James Kalkstein, PE, Chief Engineering Officer and Principal, Limestone Engineering Services, LLC

Limestone Engineering Services, LLC (LES)

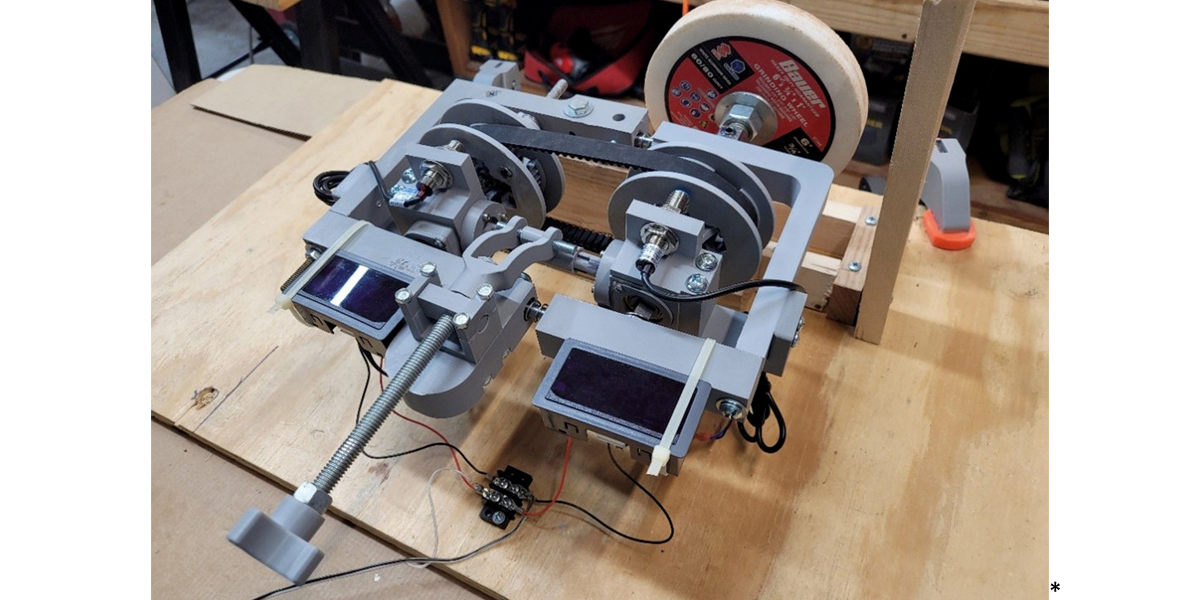

Limestone Engineering Services, LLC (LES) has continued development of our unique and patented CVT under patent #11,371,592. The development has moved from the Research Proof-of-Concept Prototype as shown in the patent disclosure to an engineered Development Prototype (DP#1) shown in the figure below (Figure#1).

*Figure #1: Development Prototype #1 (DP#1) on Test Bench Setup

The DP#1 is constructed from 3D-Printed Hyper-PLA material. This material is rated at a tensile strength that is approximately 20 % of the strength of typical aluminum. Therefore DP#1 has a limited torque capacity when compared to a full-production metallic unit. However, the belt is a production-ready 5Mx15mm cog-type timing belt with a torque capacity of approximately 95 N-M (70 lb-ft). The gear-ratio span for the DP#1 unit is setup to be from approximately 1.2:1 to 0.8:1.

The ratio-change actuator in the DP#1 uses a threaded rod to actuate the devices that changes the ratio. However, the patent includes actuation devices of any kind, including but not limited to; 1) electromechanical; 2) hydraulic, or 3) pneumatic.

Please note that:

1. Virtually any timing belt width and pitch is possible allowing for virtually any torque capacity and;

2. Ratio spans are a function of the physical size of the unit and can be increased or reduced by design.

Several design iterations have been made for the idler pulley arrangements. All proved to be satisfactory, and the final choice should be based on the final design chosen.

Testing:

This DP#1 has been tested on a test bench using a simple Prony-Brake absorber system. The test-applied torque/speed capacity is approximately 20 N-M (15 lb-ft) maximum at approximately 1,000 rpm. Please note that this is using non-metallic Hyper-PLA material and not aluminum or other metallic material components. Additionally, the input drive device was limited to these values (20 N-M (15 lb-ft) @ 1,000 rpm). We believe that this testing level was very close to the ultimate-strength of the component design using this Hyper-PLA material. However, a material change (e.g … to aluminum or steel) should bring the capability to the level of the belt ultimate-strength without any additional design changes.

Cost and Supply Chain:

The supply chain for the DP#1 requires no special components for belts, fasteners, or bearings (rotational, thrust and linear). They are all Commercial Off-The-Shelf (COTS) items. However, the main operating components are specially designed for this application. We have investigated small batch fabrication for a small number (~ 5 units) of DP#1 for full-power test-bench testing. We estimate that these units would cost approximately $500 − $750 per unit to produce, not including assembly labor and special assembly fixtures. We estimate that in series-production, the cost would fall by, at a minimum, one order of magnitude , but could have even greater reductions in larger volumes.