E-mobility gives rise to new challenges in drivetrain testing

Vehicle acoustics are essential for driving comfort and safety

New approaches to NVH testing from ATESTEO, the drivetrain testing market leader

Throughout the world, including since recently at its new testing location in East Lansing, Michigan, the leading drivetrain testing specialist ATESTEO demonstrates how OEMs and powertrain developers can sustainably optimize powertrains using early drivetrain testing. This applies in particular to NVH in electric vehicles.

Developments in New Mobility are strongly driven by electromobility. Completely new powertrains provide emission-free propulsion in vehicles. To ensure the quality, performance, design, efficiency, and comfort of future standard production vehicles from the outset, the drivetrain and powertrain are tested at an early stage of development.

Developments in New Mobility are strongly driven by electromobility. Completely new powertrains provide emission-free propulsion in vehicles. To ensure the quality, performance, design, efficiency, and comfort of future standard production vehicles from the outset, the drivetrain and powertrain are tested at an early stage of development. Vehicle acoustics, including noise and vibrations, play an important role in driving comfort. Electric drivetrains have the advantage of being quieter; thus increase driver comfort. However, the noises of the gearbox and power electronics are no longer masked by combustion engines. The quieter electric vehicles become, the more prominently the noises of the subsystems and aggregates are perceived. This is why measuring the acoustics of electric drives is becoming more and more critical to success.

NVH behavior of the electric powertrain and its effects

NVH phenomena (noise, vibration, harshness) are audible or tangible vibrations in the vehicle. The aim of NVH testing is to recognize and avoid these vibrations during drivetrain development. NVH phenomena in e-mobility arise primarily through new components with higher frequencies such as inverters and e-motors. Gear noise and rattling and clonk effects can also arise from these components.

How NVH phenomena arise in the e-drive unit (EDU): The elastic deformation of the transmission, along with tiny manufacturing deviations and tolerances, leads to tooth contact creating a dynamic excitation as a source of noise. The shafts and bearings transfer this excitation to the housing. The housing in turn radiates the dynamic energy. In the resonance areas of the housing, the vibration becomes audible. Other parts such as the mounting system or side shafts can also transmit the excitation to the body of the vehicle, which in turn also radiates the noise.

How to counter NVH phenomena in development and testing

The inverter, e-motor, and cables, along with new transmission designs for high speeds, lead to new challenges for NVH testing. Certain inverters have thin and flat housings that tend to radiate the noise at natural frequencies. New transmission designs feature planetary gears with high speeds and interaction between motor shaft and sun gear. The challenge of optimizing the NVH properties of the inverter lies in IGBT clocking. The inverter has a high unpleasant frequency around 10 kHz and can emit electromagnetic disturbance (EME). An electric motor runs at speeds of up to 25,000 RPM, which leads to high sound radiation. Testing service providers need to react to these changed requirements by finding new solutions. For example, quieter test cells are needed to test e-drive units, special frames with a high degree of stiffness have to be built. High-speed test bench motors are required to test fast-running e-motors and reduction gears.

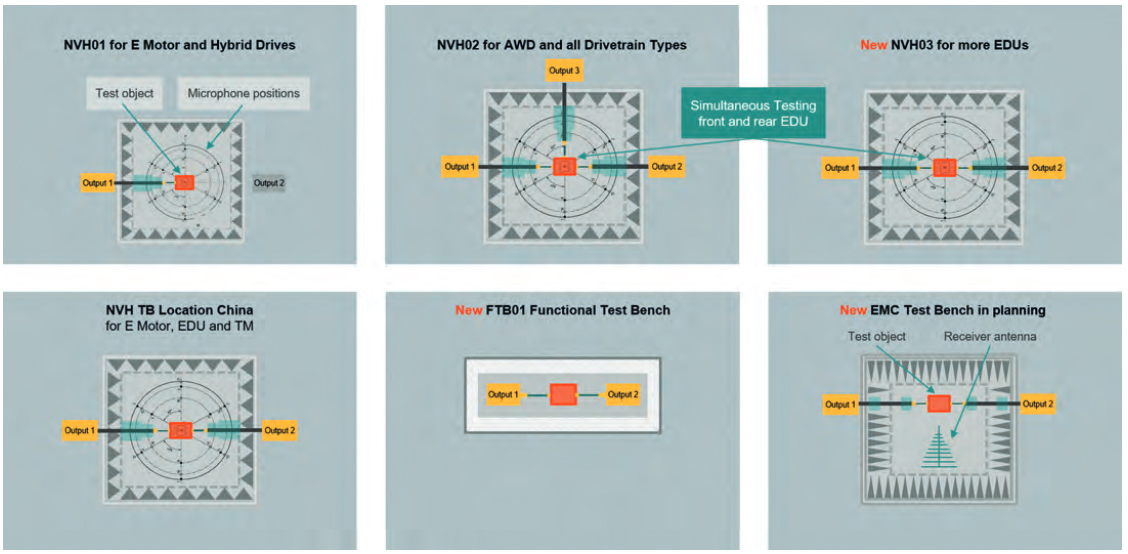

Success factor 1: high-performance NVH test benches. To fulfill the higher demands of NVH testing in e-mobility, ATESTEO developed two new NVH test benches with 700 kW and 1,000 V DC power plus a new high-performance test bench with an inverter with 10 kHz IGBT clocking and a fast speed and torque controller. ATESTEO employs the test benches to conduct very dynamic test cycles for simulating real conditions of operation.

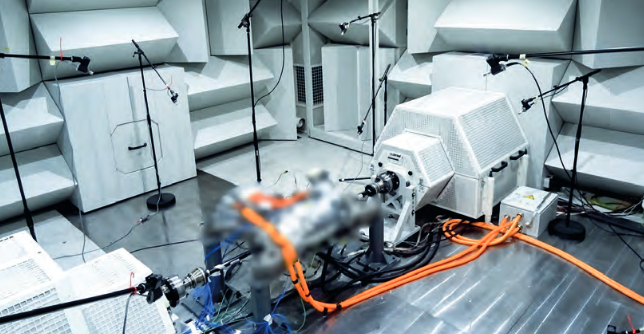

Electrical Drive Unit (EDU) for sound power measurements with 10 microphones

- Triaxle and uniaxial acceleration sensors:

- Important positions are bearings, large surfaces, EOL point

- Rubber mounting position at active and passive side

- High damping frame

- Factor of ten times stiffer than the engine mounts

- Original rubber mounting at the stands

Success factor 2: a high-speed test bench motor. At ATESTEO, a key test bench component for NVH testing on EDUs is a completely liquid-cooled high-speed test bench motor with a maximum speed of 25,000 RPM with vibration of less than 1 mm/s RMS. The motor can apply a torque of up to 600 Nm with an efficiency of 96.5 %

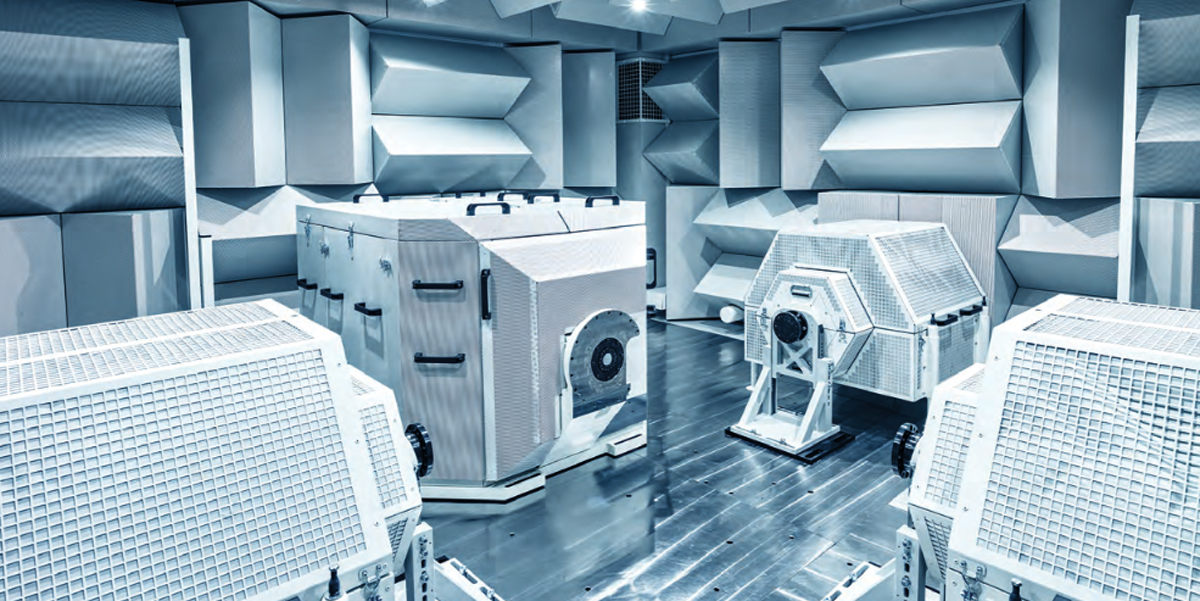

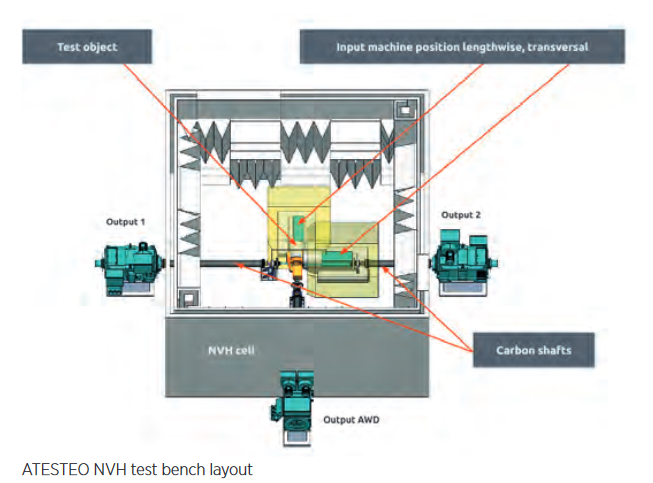

uccess factor 3: an innovative test bench layout. All components of the EDUs, transmission, and e-motors can be tested on the NVH test benches at ATESTEO. The 6.5 by 6.5 meter large ISO 3745 class 1 acoustic chamber contains a 60-tonne decoupled test bed. The frequency range is 150–16,000 Hz with the background noise level of less than 35 dB(A). The DC 1,000 V, 1000 A, and 700 kW power ratings fulfill all the requirements of high-performance electric vehicles.

Success factor 4: EMV testing. The electrification of drivetrains leads to the necessity of testing the electromagnetic compatibility of the electrical components and systems in the vehicle. For this purpose, ATESTEO is planning an EMC test bench with a semi-anechoic chamber for measuring emissions in accordance with CISPR25 and immunity measurements in accordance with ISO 11452. The chamber focuses on the testing of electrical components such as EDUs, e-motors, or inverters under full load and maximum speed. Specifications: 1200 V and 500 A (800 A peak), 5,000 Nm torque per side shaft and a maximum speed up to 25,000 RPM for testing an e-motor.

NVH test field of ATESTEO: Currently, there are five test benches. On two identical test benches, a front and a rear EDU of AWD vehicles can be run simultaneously, which shortens the test time. Commissioning and parameterization are carried out on the high-performance functional test bench.

Equipped for the mobility of the future

The new challenges of e-mobility are clearly presented and solved in the testing environment. OEMs require the full spectrum of NVH testing, especially for testing and avoiding new NVH phenomena. Competence, experience, and technological know-how are what is needed. Leading drivetrain testers such as ATESTEO offer the entire spectrum of NVH testing on test benches developed in-house according to the highest standards with detailed knowledge of their working behavior. They test wherever powertrain development takes place. ATESTEO now conducts testing at its site at the heart of the American automotive industry, in East Lansing, Michigan, offering testing sites in Germany, China, and Japan as well.