Xiao Cai, Chairman & CTO, Stropower Technologies Co., Ltd.

- The correlation factors between the NVH performance of e-drive vehicles and its inner high-voltage power network

- Extensive impact of underlying electrical fluctuations and transients on electric drive vehicles

- Development of industry testing standards and testing environment

A key difference in NVH performance between e-drive vehicles and internal combustion engine (ICE) vehicles lies in the electromagnetic excitation vibration caused by the vehicle’s electric drive, such as the humming of the battery pack and the characteristic noise of the motor‘s electrical speed in the high dynamic region. This is the NVH characteristic of the high-voltage system of e-drive vehicles that can be perceived when exposed. However, through a deeper understanding of its mechanism, we will see more widespread high-voltage electronic and electrical fluctuations and transients, which more often and silently affect the control performance – functional status – driving experience – safety and durability of the electric drive. Effective high-voltage testing can help us better predict these potential hazards.

The correlation factors between the NVH performance of e-drive vehicles and its inner high-voltage powernet.

The mechanical structure design and power transmission design of the vehicle body form the self-foundation of the vehicle’s NVH performance. With the assistance of good chassis suspension, noiseabsorbing layers, and wind noise isolation, luxurious and quiet models can achieve better NVH performance in terms of mechanical quality. This is a very important design field in the automotive industry. These measures and means are effective and primary for mechanical vibrations below 100 Hertz. However, in electric vehicle models, there are typical noises in the kilohertz frequency band. These comparably highfrequency noises cannot be effectively suppressed by the absorbing materials and traditionally designed body structures, nor can they be masked by other low-frequency noises due to the difference in timbre. And it suddenly brings about new problems in NVH engineering for e-drive vehicles.

The difference in noise sources is the cause of different timbres. The main noise sources existing inside e-drive vehicles are the electrical fluctuations and transients of the high-voltage system caused by the operations of various power semiconductor switches.

A typical phenomenon can illustrate this issue: when charging your laptop with a charger in a quiet room, in most cases, you can clearly hear the humming sound of the charger. This is a common acoustic noise in daily life caused by electromagnetic fluctuations. The reason is that the power transmission control of switching power supplies relies on the switching actions of power devices. During the use of electric vehicles, similar causes of noise can also often be found: a faint humming sound that can be heard even when the vehicle is not in motion after just being powered on, and the special tonality variation in accordance with your pedal position.

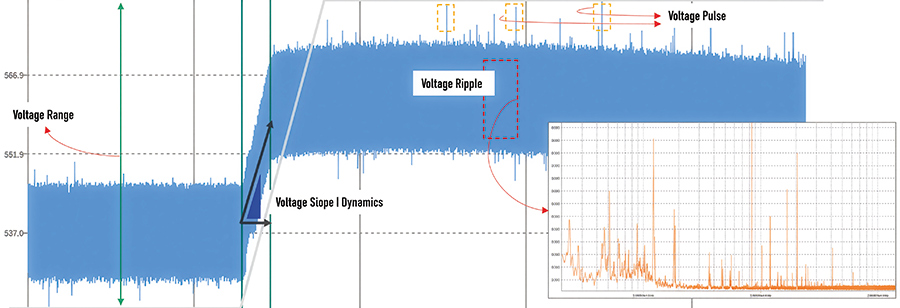

During the power fluctuation of several hundred kilowatts (x kW) in an electric vehicle, the voltage and current of the internal highvoltage system will be subjected to electrical fluctuation impacts of varying speeds, ranging from 1V/MS to 1V/ns, for example. In terms of the composition of the high-voltage system, different electronic and electrical units inside are connected in parallel to the DC bus supported by lithium battery packs and DC link capacitors, and they will experience varying degrees of interference.

By conducting ripple injection tests on the lithium battery packs of e-drive vehicles ranging from 10Hz to 150kHz – that is, by simulating the ripple amplitude of the DC bus voltage and applying it to the power battery pack, the acoustic noise spectrum generated by the power battery pack was tested.

From the test results: due to the high-voltage battery pack characteristics of power batteries, there are several uH components in their internal impedance characteristics in the equivalent model at the circuit level. This enables ist response to fluctuations in AC voltage to generate an AC current with a sufficiently high phase difference – that is, the AC current intensity of the power battery pack varies with frequency according to its own impedance-frequency characteristics (D-EIS or in-situ EIS). This also leads to the NVH noise tones produced by the fluctuations of bus voltages of different frequencies on the battery pack being quite distinct. Based on the current test results, the corresponding relationship between the magnetic field stress of the current and the structural vibration (such as copper bars and metal covers) also confirms the causal relationship of frequency correspondence.

Effective control of electromagnetic interference fluctuations that may generate NVH excitation is currently an important research topic in high-voltage electronic and electrical testing. However, due to the very wide differences in the „excitation – transmission – response“ path among different vehicle models, the applicability of general models is limited. More prediction and verification methods still require appropriate test platforms for verification.

Take the electric drive power unit as an example. Under different power density design requirements, the controlled performance of the motor and the electrical shocks, such as ripple and surge, caused by the high-voltage system during the power output process, are related to the designer‘s optimization level of the control process, as well as appropriate peripheral filtering and anti-interference measures. The final production vehicle’s torque ripple wave and NVH characteristics are the result of design efforts coming from multiple aspects.

Extensive impact of underlying electrical fluctuations and transients on electric drive vehicles

The above description of the explicit NVH performance of vehicles has revealed the impact of electrical fluctuations and transients within the high-voltage system of e-drive vehicles on them, a problem that has not been encountered in ICE models.

In fact, since the large-scale commercial use of electric vehicles began, vehicle problems caused by the dynamic stress of high-voltage electrical systems have been very frequent, and most of these problems do not occur in a way that drivers can perceive.

For example: due to the excessive AC current at the impedance resonance point formed by the high-voltage wiring loop, the relay disengages and the BMS protection signal is mistakenly triggered; the overvoltage warning shutdown of the TMS is triggered by the voltage fluctuation of the DC bus caused by the operation of the MCU; the overvoltage of the DC bus which caused by the energy regnerated during heavy braking, which breaks down the components, etc. From the various electrical dynamics of high-voltage systems that have been mentioned, the major types of threat factors that mainly emerged can be classified in terms of waveform as:

1. Ripple during steady status

2. Transients during dynamic motion

Among them, the steady-state ripple mainly refers to the regular fluctuations in the bus voltage caused by the controller during the process of stabilizing the power output.

Under normal circumstances, since the on-off control of the switching elements by the controller is implemented by the software, if the load current fluctuates within a defined tolerance range, the command response for a stable Output is completed. This process is usually achieved at a steady state through „feedback-control“, such as typical PID control or complex PID control with algorithm update functions. The timing pulses of the switch nodes formed by the on-off control constitute the AC excitation of the entire in-vehicle high-voltage system, and through the impedance network of the system, the bus current is ultimately formed – this is a typical controlled response. Therefore, the level of ripple is directly related to the excitation composition, which is also the key way to usually increase performance or avoid the frequency of feature problems through control and regulation.

Transients during dynamic motion often occur in an „uncontrolled“ state, such as in a typical load-dump situation: the energy shock and high-voltage pulses generated by the drastic changes in current are natural responses without any controller management, and the survivability of the component unit solely depends on the stress margin at the time of design.

Another type of transient occurs with a higher probability. It also appears at the semiconductor nodes of the power bridge; that is, during the instantaneous process of the bridge arm switching, the voltage or current pulse is commonly seen at the rising and falling edges of the switching waveform. Although these transients cannot be regarded as truly „uncontrolled“, in fact, once a piece of hardware design is completed, it is very difficult to make changes to the ramping rates.

So, it is not difficult to see that the main difference between ripple and transient lies in the rate of voltage change, that is: V/s. Inside e-drive vehicles, with the development of the design trend towards functional integration, more and more functional units are gradually integrated into the same high-voltage system. For instance, several inverters are added to achieve an outdoor power supply, a step-up and step-down voltage module is added to be compatible with high and low voltage charging piles, and a 48V module is added for functionality and comfort, etc. Different units operate at different frequencies, which will apply more voltage variability on the DC bus. As a result, the generation of interference and the verification of anti-interference become important.

Development of industry testing standards and testing environment

At present, the industry is still in the research and early standard establishment stage for the design control and suppression countermeasures of ripple and transient pulses in EVs.

Conducting electronic and electrical tests on the high-voltage system of electric vehicles can simulate the extremely large electrical stress that occurs, thereby verifying the safety design margin and functional anti-interference capability of each component unit inside the vehicle. Avoid situations that threaten driving safety and affect the driver‘s experience.

Starting from the early LV123 standard, mainstream European car manufacturers have made many early efforts in the high-voltage electronic and electrical testing standards of vehicles, such as VW80300.

Today, the main general standards referred to in the industry are ISO 21498-1, -2. Since 2023, Vehicle manufacturers and testing institutions in China have gradually begun to pay attention to the corresponding testing standards and have already made preparations for the release of the corresponding Chinese standards as the testing progresses, and it is expected that the corresponding standards will be released within the next one or two years. In the future, based on the relevant test results and the accumulation of more new test cases, there will also be updated standards to gradually improve the current test standards, enabling them to provide more valuable references for detecting potential design issues of vehicles.

Stropower Technologies has always been dedicated to the development of green energy and the Research and development of zero-emission vehicles R&D. As a major equipment supplier for lithium battery testing and a leading enterprise in the electronic and electrical testing of high-voltage systems for electric vehicles.

Since 2018, based on the VW80300-2016 standard, the world’s first vehicle ripple spectrum response analyzer that fully meets the standard requirements has been developed by Stropower Technologies. Subsequently, it became the first supplier to offer a complete set of test equipment, including different voltage ramping rates and transient pulses.

Stropower Technologies officially released the third-generation vehicle high-voltage electronic and electrical complete test solution in October 2024, which includes a wide-frequency ripple disturbance emulator, a program-controlled test power supply system up to 1200V-1000A, a high-voltage artificial network that fully meets the impedance spectrum characteristics, and other auxiliary test equipment modules. It is a leading test solution provider in the industry that fully complies with test requirements and can comprehensively cover the main power dynamic ranges.

Thanks to the vigorous development of the electric vehicle market in China and the long-term trust and support of major vehicle manufacturers and testing institutions for Stropower Technologies, through the accumulation of hundreds of test cases, the company can not only provide customers with a one-stop complete set of test equipment assembly solutions, moreover, it can provide customers with professional and predictive test environment setup based on their testing purposes and the characteristics of the objects under test, avoiding time waste caused by the lack of understanding of tests and interferences from related variable factors. It also offers professional suggestions and technical support for the correct conduct of tests and the accuracy of test results.