Marco Silvestri, Chief Engineer, Dana Incorporated

Across all our actions, we never lose sight of a guiding vision toward a zeroemissions future. This has powered our first-mover advantage in electrification.

At Dana, we strategically invest in technical competence − designing, engineering, and manufacturing the components of a complete e-Propulsion system in-house. These innovations include efficient EV systems and new electrodynamic products like motors, inverters, controls and software, battery cooling systems, and metallic bipolar plates for fuel cell applications.

The legislation for pollutants and emissions is driving OEMs to design their reduction programs to align with aggressive timelines — accelerating the adoption of electrification. These mandates, coupled with corporate commitments from OEMs, will significantly increase the demand for electrified vehicle architectures, the main components of a Battery Electric Vehicle.

The legislation for pollutants and emissions is driving OEMs to design their reduction programs to align with aggressive timelines — accelerating the adoption of electrification. These mandates, coupled with corporate commitments from OEMs, will significantly increase the demand for electrified vehicle architectures, the main components of a Battery Electric Vehicle.

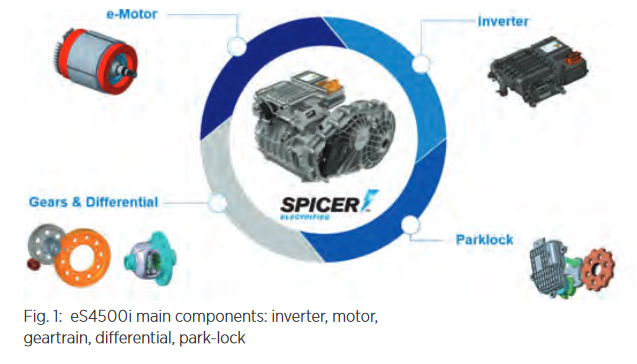

Dana’s solution is the Spicer® Electrified eS4500i e-Drive Unit − a highly versatile 3-in-1 electric drive unit (EDU) that converts the stored electrical energy from the battery into mechanical power to the wheels.

eS4500i Platform

Utilizing competencies from Dana’s global network of technology centers, the highly integrated eS4500i comprises an inverter, motor, one-speed geartrain, open differential, and optional park-lock.

The thinking behind the eS4500i was really to provide more than a single EDU. What was needed was a versatile platform offering multiple ratios and integrated design of motor and gearbox while also taking into consideration efficiency, optimized packaging space, and lower weight.

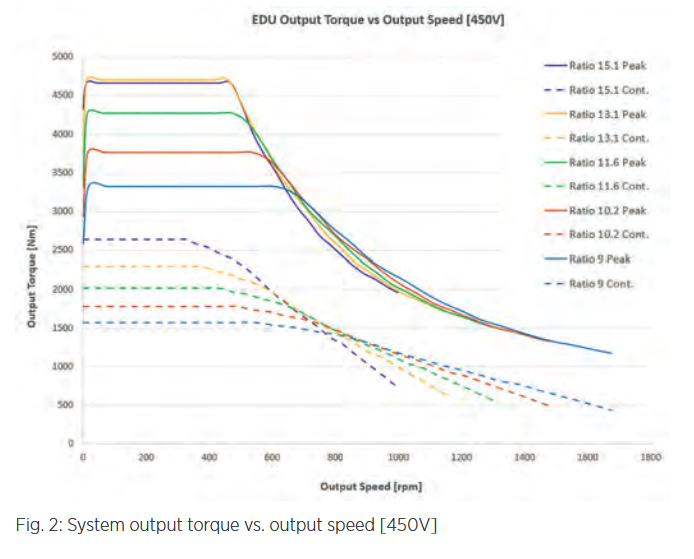

To cover multiple applications, five different ratios were designed (macrogeometry) with the same center distances, same gear width, and similar envelopes diameters also recombining the same gears to reach five different ratios.

In this way, with a unique design of the housing and bearings, the eS4500i can host five different gear-trains to be able to match different vehicle requirements in terms of maximum torque and speed. From figure 2, it’s appreciable the spread of torque and speed that the system can cover with the five different ratios options. A limitation of around 4,500 Nm (as max nominal output torque value) has been decided for ratio 15.1 and 13.1 because of match with other Dana products but useful in case of demanding vehicle gradeability and high continuous torque.

Highly Integrated Layout

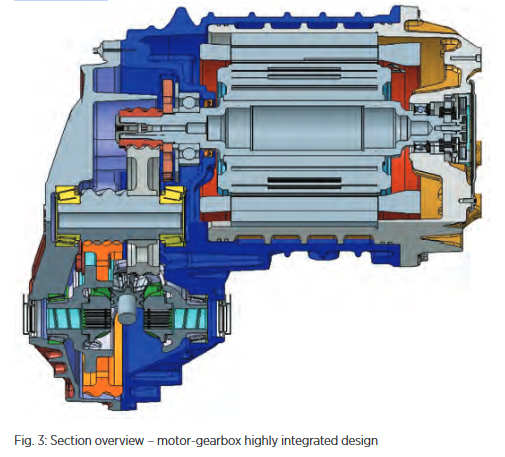

The design of the gearbox and the motor was improved by integrating the components as much as possible to provide a light, compact, and power-dense EDU.

For the eS4500i, it has been decided to have a highly integrated design between the motor and gearbox to save weight and to improve the power density.

Only three housings compose the structure of the EDU and shape two separate environments: a dry one for the motor and a wet one for the oil-lubricated gearbox.

Referring to figure 3, from right to left:

The motor back-case supports the rear motor bearing and becomes the seat for the stator and the internal side of the motor cooling jacket. The helical cooling path is made by die-cast molding for manufacturing efficiency.

A carrier housing supports the front motor bearing and becomes one of two gearbox housings as well as the external side of the motor cooling jacket to complete the sealed channel.

The cover housing enclosures the gearbox components.

One of the main characteristics of the highly integrated layout is the over-hanged pinion gear directly mounted on the head of the rotor shaft. Between the pinion gear and the motor front bearing, there is a parking gear.

The layout is completed by an intermediate shaft and an open differential, both supported by taper roller bearings.

This new layout reduces the interfaces between the gearbox and the motor to achieve a precise axial centering of the gearbox with the output shaft of the motor. This also allowed a significant reduction of components like having only two bearings on the input axis, a reduction of the number of housings and a significant a reduction of fasteners.

The EDU is completed by the inverter that is direct-mounted on top of the motor with the high voltage connections passing through the back housing.

The park-lock adds another degree of flexibility because it can be added or removed on customer request. This park-lock option is already patented and in series production, with a mechanism layout now upgraded with a new smart actuator.

Motor and Inverter

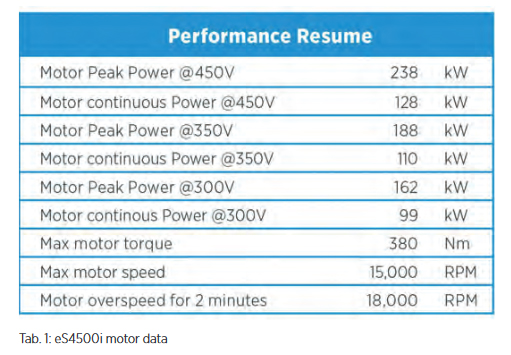

The eS4500i is powered by a propulsion system composed of an asynchronous dry 450V motor and with a Dana 2nd generation directmounted inverter.

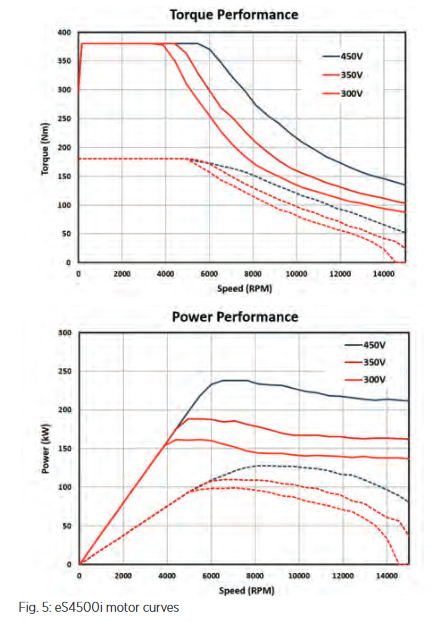

The propulsion system is cooled by water-glycol and the theoretical performance curves are shown in fig. 5 at 65°C coolant temperature.

Since this propulsion system is for a medium voltage (450V) application, Dana decided to use the latest IGBT module technology for this inverter over the newer SiC MOSFET technology. This allows the use of our proprietary Reflex gate driver technology to achieve the most cost-effective solution for this voltage range.

Conclusion

As a Tier 1 supplier, Dana offers its new eS4500i EDU, an off-the-shelf solution on the path to electrification, with a compact and light package for a wide range of applications.

The eS4500i is equipped with the well-known Dana differential from a robust off-road heritage, with an optional park lock system.

Dana is offering its all-new configurable off-the-shelf eS4500i EDU to a multitude of segments and applications. This work is the result from the synergy between the different technical centers and other global Dana branches, putting together different competencies. With its power density, reliability, and cost competitiveness, this product will contribute to our customers’ success on the path to electrification.