- Solutions for OEM customers, niche low volume manufacturers, aftermarket and gearbox only customers.

- Packaging two motors in the space of one

- Aftermarket vehicle conversions

- Thermal robustness and efficiency

Passion for fun to drive has always been in the the DNA of TREMEC. For ICE vehicle platforms, high performance versions of mainstream vehicles are typically realized with an upgraded engine and transmission solution, e.g. bigger engine displacement, supercharging, higher torque transmission or even different transmission architecture. As an example, a Ford Mustang GT500 utilizes a supercharged V8 and a DCT instead of a turbocharged I4 or naturally aspirated V8 and planetary automatic transmission in the standard Mustang.

For a battery electric vehicle, it is less straightforward to create a high performance derivative. While a higher current inverter may unlock some additional performance from the electric motor, a large uplift in power and torque will only be possible with a bespoke EDU and battery solution that is specifically designed and system-optimized as a high performance unit.

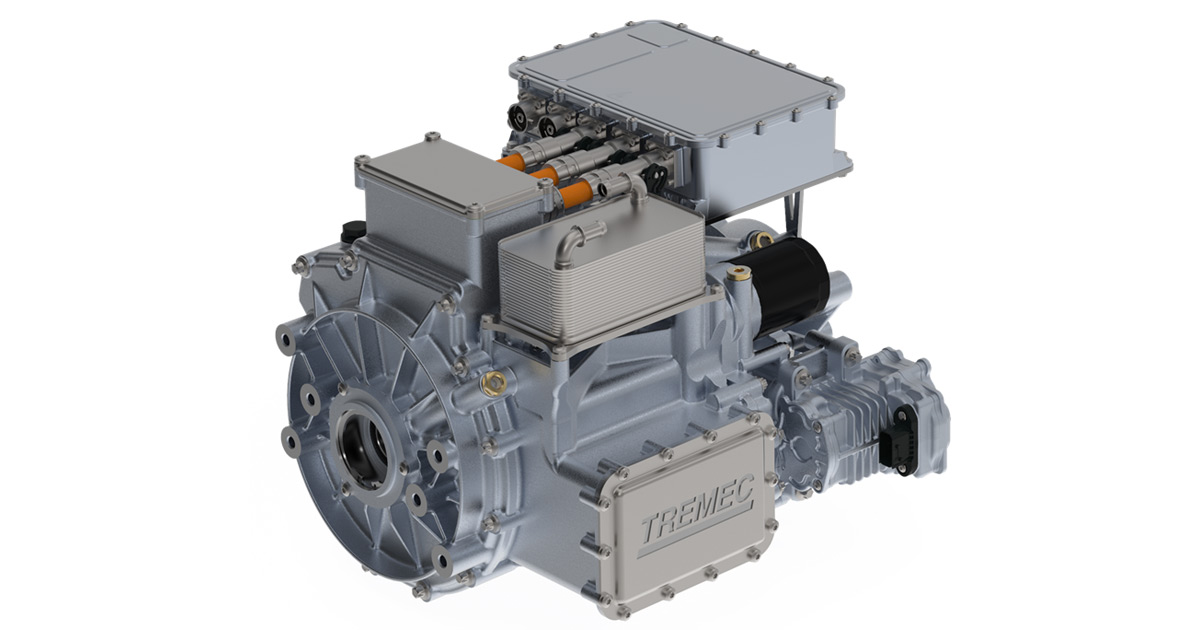

Recognizing the need for many OEM’s to find such bespoke high performance solutions to replace the standard e-drive componentry in a given platform, TREMEC has developed a first generation of EDU’s for that purpose, with a torque vectoring rear EDU as first product offering. Targeted initially to the high performance SUV and GT car market.

Also recognizing that many more niche low volume vehicle manufacturers are looking for Fun To Drive electric drivelines TREMEC has developed low volume solutions offering high performance and low footprint.

As TREMEC is also known for it’s aftermarket business a solution is being developed for converting ICE car’s to BEV, keeping the high performance and fun to drive factor.

Bench test results, vehicle builds, thermal robustness and efficiency results are presented.

Author

Nico De Visscher, Chief Engineer Design & Development

nico.devisscher@tremec.com

www.linkedin.com/in/nico-de-visscher-65031135