Joe Tolkacz, Chief Engineer, Stellantis

The Stellantis RAM 1500 Ramcharger is the first of its kind in the US market – a light truck with a pure serial range extender drive, a range of 690 miles, and two e-drives providing 647 hp in total. We spoke to Chief Engineer Joe Tolkacz, who presented the Ramcharger at the CTI Symposium 2025 in Novi. We were particularly interested in the additional utility value, compared to a conventionally powered light truck.

Mr Tolkacz, you could have built a ‘classic’ parallel plug-in hybrid. Why did you pick a serial hybrid?

When you switch from electric to serial hybrid drive, when the engine starts making torque, the start-stop capability and smoothness are very transparent to the customer. The other thing is that we are working on a battery-electric-only version, and we will be able to reuse many of the components from the range extender on the BEV. The electric drive modules and the charger work very well in both the electric rangeextended vehicle and the BEV version. Basically, you could take the Ramcharger, take the engine out, and you have a BEV. Those were two big factors for us.

Some people say P2 hybrids have better load and towing capacity, because there are no thermal issues with an engine drive. How did you handle that with the serial hybrid?

The first thing we did was a lot of analysis. We have capable tools for estimating our towing capacity and other performance attributes. These tools helped us to work backwards to design the motors, the batteries, and other components. With the tools, we can do more than just typical EPA cycles. We have the capability to simulate the Davis Dam test, which includes towing on an 11.4-mile slope with a 3500-foot altitude difference, for example. We can also simulate 65 miles cross-country towing, and we can simulate the Eisenhower pass in Colorado. So we have a lot of great simulation capabilities. We broke the results down to the subsystem level. We tested the heck out of all components, put it all back together, and now we’re finishing up on the vehicle side to ensure that the simulations correlate well with what we saw in the vehicle. If we find things that don’t quite correlate, we can go back to the simulations and correct them. That helps us to preverify design changes. You know, we want to have a no-compromise vehicle for the customer, so that was our guiding principle from the start – from the simulation through the vehicle design and testing.

Given the traction requirements, why don’t you have gears for the e-drive, or for parallel hybrid mode?

One of the things you get into when you have these additional gears, such as when you have a multispeed gearbox or multi-speed e-drive, is where the shifts occur. It’s challenging to make those shifts transparent. But the key point is, we don’t need any gears for traction reasons. Another advantage of having no gearbox for the engine drive is that we have a lot of flexibility with engine positioning. We saw that multi-gears were not needed, the complexity was not needed, and the drive disturbance was certainly not desired. One of the main reasons for studying a multi-speed gearbox for the e-drive is when you are limited in your motor capabilities. Fortunately, for this vehicle, the top speed isn’t crazy – it is in the region of 115 mph – so our motors were able to achieve that with a 15:1 gear ratio. You may need multispeed gearboxes for some performance cars with higher speeds, where you may have an issue with the motor speed. So we are pretty comfortable with where we ended up.

The generator has much less power than both drive motors. How do you continually ensure full power supply during serial operation?

We do have modes where the battery power plus generator power can result in the electric drive units being capable of making 500 kW. If we claimed that we had e-drives that could achieve 500 kW theoretically, but not in any practical situation, that would look awkward. As for steady-state conditions with continuous power requirements, for me it was pretty surprising that we can tow our max Trailer cross-country at 65 to 75 mph, and our generator keeps up with our power requirements. We don’t ever deplete the battery in these conditions. As I mentioned in my speech here at the CTI symposium, we have some special modes. For instance, if we’re towing a trailer uphill, say, up Davis Dam at 120 °F (49 °C), we know we have a lot of thermal load. So when a customer anticipates such a scenario, he can push the ‘tow’ button, and we pick a different state-of-charge point that allows for maximum load towing in charge sustaining mode. Or we have the ‘e-save’ button that preserves the state-of-charge, and so forth. So there is a lot of flexibility there. We’ll have to do a good job of educating drivers to make sure they take advantage of all these opportunities.

Which axle design did you choose to enable off-road capacity?

We designed the Ramcharger with independent front and rear suspension and frame-mounted drives. Ordinarily, that’s not the choice for off-roaders. We did that intentionally because we didn‘t want to compromise the on-road experience. Many people never go off-road; they don’t even tow anything. The ramcharger is their family vehicle. They want it to be luxurious and comfortable. However, we added some features to balance that trade-off, for instance, the electronic locking differential, or active suspension, so you can raise or lower the vehicle. These features are good ways to satisfy our off-road customers.

What extra utility value does the Ramcharger offer, compared to traditional powertrains in this segment?

You know, 14,000 pounds is a pretty nice towing capacity! If you compare that to some of our competitors, it’s close to medium-duty capability, it’s really a lot for a light truck. We have 690 miles of range, which is not far off from diesel territory. I took a compass and drew a circle around Auburn Hills, to see how far I could get with those 690 miles. It covers a lot within the USA. You can get to Kansas City, St. Louis, or up to Quebec City in Canada. Then we have these V2X features that conventional drives cannot offer. That, to me, is a huge selling point for a truck. I love the idea of having a power panel to plug stuff in at my cabin in northern Michigan. You don’t always have extension cords to reach from where the outlets are. I can move the car around my property and use it for any kind of electric equipment I have. It can be useful when people are building homes before electricity reaches the site. So they can run their circular saw, their tile cutters, or whatever they need to run, off the battery of their truck. And there are also these guys on primitive campsites in a national forest area, for example, without any electric outlets. Another thing in the US, especially in college football, is tailgating. That’s when people drive their trucks to the stadium and sit in a parking lot for a picnic. Sometimes you see people with television sets, electric pots with barbecue pulled pork, or other things. For that kind of adventure, there’s the word glamping, which means glamorous camping. The Ramcharger supports all these activities.

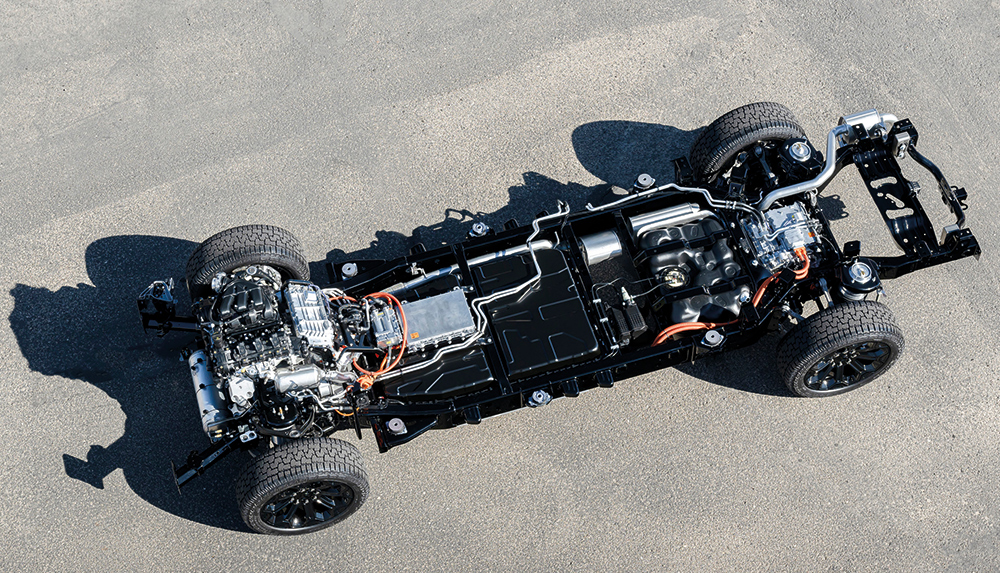

The front and rear e-drives, engine-generator unit, and the battery of the Ramcharger are mounted in a frame structure with independent front and rear suspension. (© Stellantis)

What do you offer in terms of vehicle-to-home or even vehicle-to-grid, and how much of a future will this technology have?

Currently, we can do what’s called vehicle-to-home or V2Home. If you assume 30 kW, which is quite a lot, you can power a house from the gasoline and the battery for about 11 days. And if you cut that down to 15 kW, it’s about 22 days. The next thing that is coming in the future is vehicle-to-grid. The requirements haven’t stabilized yet, so we decided not to chase that. But technically, it’s quite easy to do with our baseline. Once you have V2Home, vehicle-to-grid is an easy add-on.

Interview: Gernot Goppelt