Maximilian Guettinger, CEO & Co-Founder, Emil Motors

The electric vehicle (EV) industry is experiencing unprecedented growth, driven by global demand for sustainable transportation. Yet, this momentum faces hurdles: the reliance on rare-earth magnets − primarily sourced from China − introduces supply chain risks, compounded by potential tariffs that could disrupt production and escalate costs. Amid these challenges, Emil Motors emerges as a game-changer with its Segmented Axial Flux Asynchronous Motor (SAM) technology. This magnet-free innovation not only sidesteps geopolitical and environmental concerns but also delivers superior performance, efficiency, and scalability, positioning it as a cornerstone for the future of electric mobility.

The standard induction motor and its shortcomings

Induction Motors (or asynchronous motors) are well known work horses in industrial applications and even in automotive drivetrains. They work well and do not rely on magnets. In principle an induction motor replaces the magnets inside the rotor with conductive bars. In operation the stator field rotates faster than the rotor, which induces currents in the rotor conductors. These currents then create the rotor field which interacts with the stator to produce torque. Sounds easy enough, so why are we not using them everywhere?

The issue is low power density coupled with high manufacturing expenses for high efficiency induction motors. Torque density in induction motors is much lower compared to permanent magnet designs and if you want to build them cheaply you will sacrifice efficiency. The difficult bit is the manufacturing of the rotor conductor. For a standard radial flux machine, it must be cast or assembled in a complicated welding or brazing process. The cheapest way is cast aluminum, which has lower conductivity compared to copper and results in higher losses and lower efficiency. Achieving high efficiency in a conventional induction motor requires copper rotor conductors. These can be cast with expensive molds, or they can be assembled using a costly brazing process. When going through this complicated process you will still end up with a machine that will be much heavier or less powerful than a permanent magnet motor, making it undesirable.

Emil’s mission was clear. Make induction motors more powerful with low weight and low manufacturing cost. Achieving Performance without magnets.

Unveiling the SAM Architecture

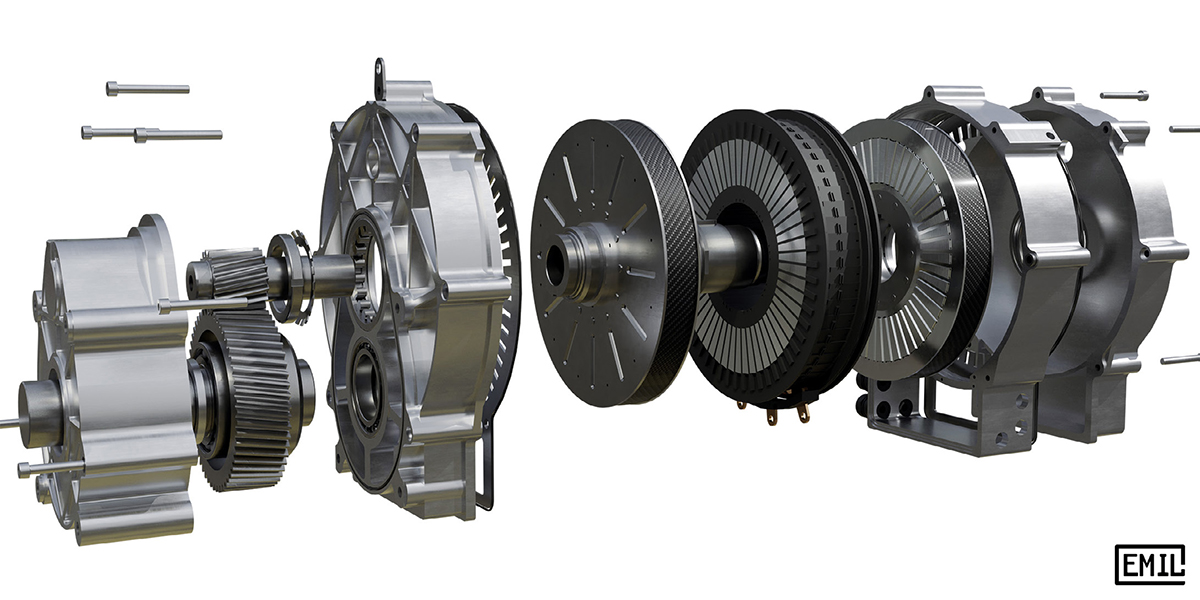

SAM’s brilliance lies in its axial flux design, a departure from the conventional radial flux motors dominating the market. Unlike radial designs, where magnetic flux flows perpendicular to the rotor shaft, the Emil’s disc-shaped configuration directs flux parallel to the shaft. This allows for a larger rotor radius within a compact footprint, boosting torque density and power output without increasing the motor’s size. The result is a lightweight, high-performance motor that punches above its weight class.

The stator is a core component towards achieving extraordinary performance. Segmented into precise sections, it achieves a slot fill factor exceeding 65 % which describes how much of the available space is filled with copper wire, maximizing space efficiency for enhanced performance.

Our fully automated winding process is exceptionally well suited for mass production – a critical advantage for scaling EV manufacturing. Conventional round wire windings achieve slot fill factors around 40 %. State of the art hairpin designs may reach 60 % but require very difficult laser welding processes or huge machines for a continuous wave winding.

Compared to this we can easily wind a coil segment by segment and use reliable well known welding processes. A similar approach was pioneered in the world of smaller electric motors in hybrid vehicles, where it has already proven itself to be cost efficient.

Meanwhile, SAM’s integrated oil cooling system sets it apart. Oil flows through channels in direct contact with the copper windings, minimizing thermal resistance and maintaining optimal performance even under high loads.

Cooling the rotor conductors is equally important in an induction motor. SAM achieves this feat by integrating cooling channels near the rotor conductors, keeping continuous power up and losses down.

Both of these revolutionary technologies, winding and integrated oil cooling are made possible using advanced plastics. Injection molding is much more manageable on small stator segments and creates advanced geometric features without increasing cost at all.

Together with our manufacturing partner Schlaeger we have developed an advanced injection molded segment design including very thin walls for slot insulation. No need for slot liners. Oil cooling channels, structural support and winding ixation all taken care of with a simple and cheap injection molding process. The best part is no part, the best process is no process.

The rotor construction is equally impressive, diverging from conventional manufacturing technology. Emil’s axial flux topology allows for major changes and innovation inside the rotor. For example, we can incorporate significant structural reinforcements on the outside of the rotor for high rotor speeds, which is much harder to achieve in a standard radial flux machine.

Manufacturing and assembly of the rotor conductor is simplified, no casting or welding is necessary. This enables the usage of higher performance alloys and a simplified manufacturing process.

As previously explained a conventional induction motor requires copper conductors in the rotor to achieve great efficiency numbers. This is not the case for SAM. The axial flux topology enables big rotor slots with a high cross section. This decreases losses, even when using a material with lower conductivity like aluminum. Additionally, the usage of different alloys makes it possible to achieve higher conductivity compared to cast alloys.

The SAM-M240 showcases these innovations:

- Peak Shaft Power: 330 kW

- Peak Torque: 450 Nm

- Max Speed: 16,000 RPM

- Efficiency: >97 %

- Active Weight: 35 kg (electromagnetic components only)

At just 35 kg of active weight, the SAM-M240 achieves a power-to-weight ratio that rivals permanent magnet motors, proving that magnet-free designs can lead the pack.

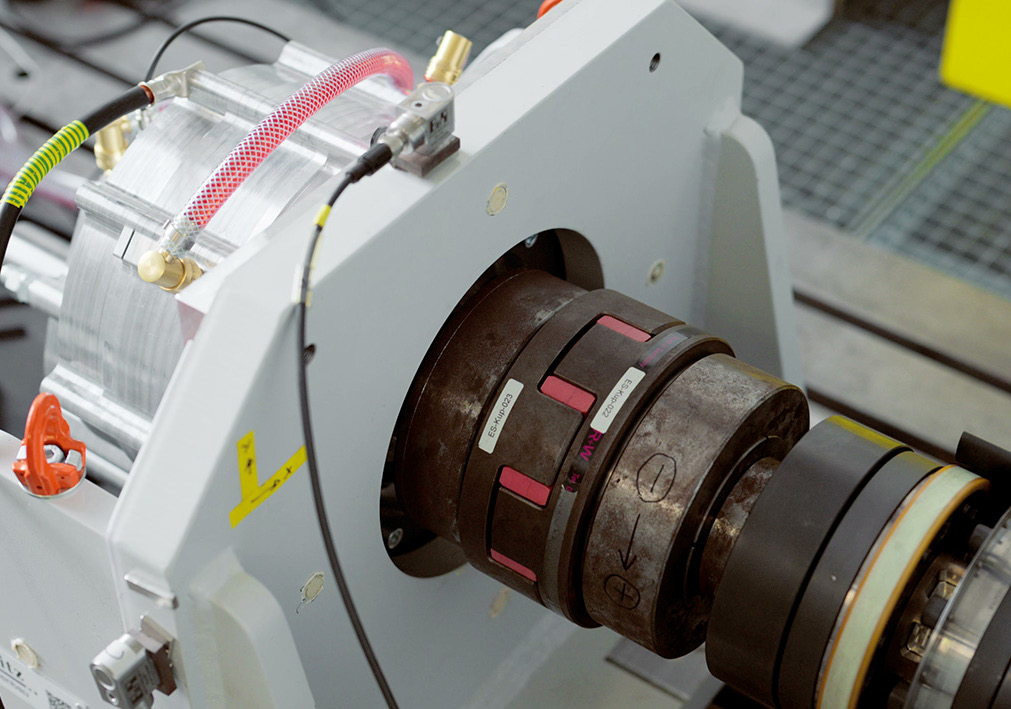

These performance claims have been validated through hours of testing data on a test bench. Talk to us directly to get more information on testing and validation of this groundbreaking technology.

A Competitive Edge Over EESM

To appreciate Emil’s significance, consider its magnet-free competitors, such as the Externally Excited Synchronous Machines (EESM) from BMW, ZF and Mahle. EESM technology replaces rare-earth Magnets with an electrically energized rotor, using current to generate the magnetic field. While effective, this approach requires additional power electronics to manage rotor excitation, increasing complexity, weight, and cost. These extra components can also introduce reliability concerns over time, a drawback in high-stakes EV applications.

In contrast, SAM relies on induction motor principles, eliminating the need for rotor excitation systems. By inducing a magnetic field through the stator’s interaction with aluminum conductors in a dual rotor setup, Emil achieves simplicity without sacrificing performance. Its axial flux design delivers torque density on par with permanent magnet motors, while its lightweight construction − just 35 kg of active mass − outshines EESM’s bulkier profile. The motor’s ability to hit 16,000 RPM enables high power capability and low motor weight.

In addition to the increased power density, Emil brings down cost by using an aluminum conductor in the rotor compared to expensive copper windings in EESM technology.

Efficiency is another win. With over 97% efficiency, SAM minimizes energy losses, extending vehicle range − a priority for manufacturers and consumers alike. Compared to EESM, SAM offers a streamlined design, higher power density, and lower production costs, making it a standout choice among magnetfree solutions. It strikes an unrivaled balance of performance, efficiency, and affordability, ready to meet the demands of mass-market EV production.

Strategic Resilience and Sustainability

Emil’s advantages extend beyond the technical. By using widely available materials like copper and aluminum, it eliminates dependence on rare-earth magnets, shielding manufacturers from supply chain volatility. To this day 90% of rare earth magnet production is controlled by China and magnet motors rely on that 100%.

Getting rid of these critical materials in your motor design is the fastest and easiest way to protect against these risks.

We have seen how quickly tariffs can get out of hand and the rare earth supply chain will take a very long time to build up in other countries than China.

For EV manufacturers, this translates to a competitive edge. Emil enables the production of high-efficiency, cost-effective vehicles without the risks tied to magnet-based motors. Its readiness for automated, large-scale manufacturing will accelerate adoption, empowering the industry to meet rising demand without compromise.

Driving the Future Forward

Emil Motors’ SAM technology is more than an engineering breakthrough − it’s a vision for a resilient, sustainable EV ecosystem. With its lightweight design, exceptional efficiency, and magnet-free architecture, SAM redefines what’s possible in electric propulsion. It challenges the status quo, proving that innovation can overcome the limitations of traditional motor technologies.

We invite industry leaders, engineers, and visionaries to experience this revolution firsthand. Visit Emil Motors to explore how we can power your next EV project, enhance your competitive edge, and contribute to a cleaner, more sustainable future. Together, let’s drive electric mobility into a bold new era.